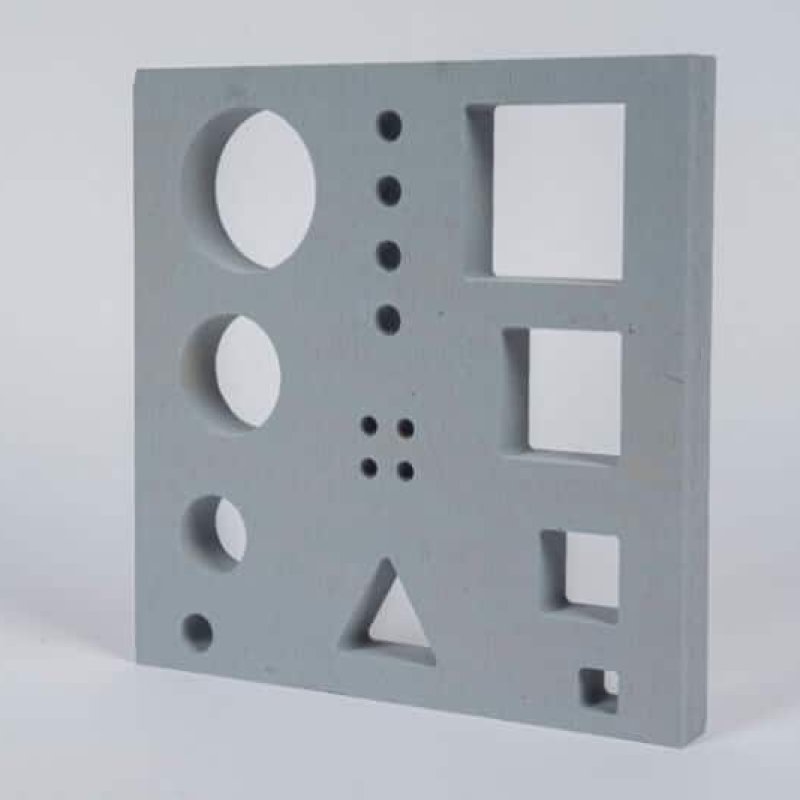

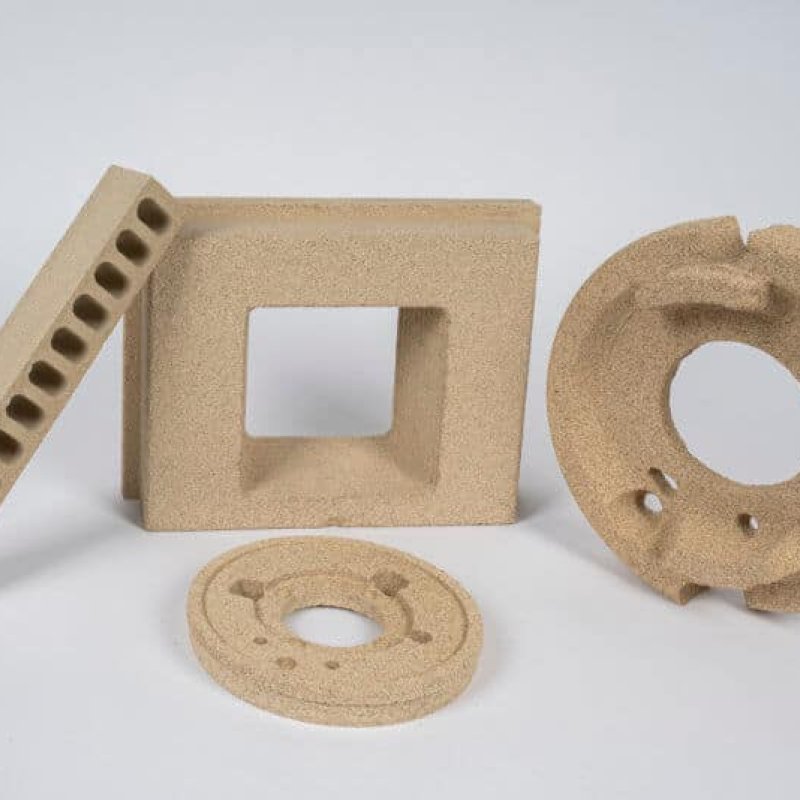

Vermiculite pressed parts

Especially in connection with the material vermiculite (also referred to as vermiculite, vermiculite or vermiculite), we rely on shaping by pressing for very large quantities.

- PRODUCT VARIATIONS

- According to customer specifications

-

Cost-oriented

Technically excellent and cost-oriented solution.

Nontoxic

Light, non-toxic, fiber-free, odorless and acid-resistant.

Refractory

Depending on the product variation, application temperatures up to 1100 ° C.

TECHNICAL DETAILS

CHARACTERISTICS

Application temperature 1100°C Schemltz temperature > 1300°C Standard panel thickness tolerance +/- 1mm Standard length / width tolerance +/- 2,5mm Linear post-shrinkage Aprox. 1% Coefficient of thermal expansion 11.0 x 10⁶ K¹ Loss on ignition 1025°C: 7% HS Tariff No. 6809.90.00 colour Sand CHEMICAL AVERAGE ANALYSIS

SiO2 46,0% TiO2 0,7% Fe2O3 5,5% Al2O3 7,0% MgO 19,0% CaO 3,5% Na2O 0,2% K2O 10,0% KS VIREboard 375 KS VIREboard 475 KS VIREboard 600 KS VIREboard700 Volume weight 375 kg/m3 475 kg/m3 600 kg/m3 700 kg/m3 Cold compressive strength 1,3 N/mm2 2,5 N/mm2 4,2 N/mm2 4,5 N/mm2 Flexural strength 0,3 N/mm2 0,8 N/mm2 1,6 N/mm2 2,0 N/mm2 Total porosity 85% 81% 76% 74% Thermal conductivity 200°C 0,12 0,14 0,16 0,19 400°C 0,15 0,17 0,18 0,20 600°C 0,16 0,19 0,20 0,21 800°C 0,19 0,20 0,22 0,22 CHARACTERISTICS

Especially in connection with the material vermiculite (also referred to as vermiculite, vermiculite or vermiculite), we rely on shaping by pressing for very large quantities. On request, the parts are available with press-in nuts for easier assembly.

Benefits

- Technically excellent

- Cost-oriented solution

- Light

- Nontoxic

- Fiber free

- Odorless

- Acid resistant

- Refractory

-

Downloads

Data sheet Vireboard VB1100-375

Product properties, typical applications and availabilities.

Data sheet Vireboard VB1100-475

Product properties, typical applications and availabilities.

Data sheet Vireboard VB1100-600

Product properties, typical applications and availabilities.

Data sheet Vireboard VB1100-700

Product properties, typical applications and availabilities.

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.