Bellows | Dressing Bellows

Bellows are elastic, hose-like protective covers made of different materials that adapt to defined movement sequences. Through the use of high-tech textiles, combined with selected coatings, they find a wide range of applications.

- Type

- Circular ring bellows | Dressag bellows

- Material

- Tarpaulin | Glass fabric | Silacate fabric

-

Temperature Resistance

Depending on the material, temperature resistance up to 1000 °C.

Protective function

Protection of machine parts as well as protection of the environment.

Handmade

Our RBS bellows are manufactured by hand in our own production.

Properties

Bellows are elastic, hose-like protective covers made of different materials that adapt to defined movement sequences. Through the use of high-tech textiles, combined with selected coatings, they find a wide range of applications. On the one hand, they protect machine parts from external influences (in particular dirt such as dust, oils, and fats) and, on the other hand, protect the environment (eg from heat, liquids, flying sparks, and dust). RBS bellows are always made by hand exactly to your specifications.

Advantages

- Temperature resistant

- Protective function

- Made by hand

- According to specification

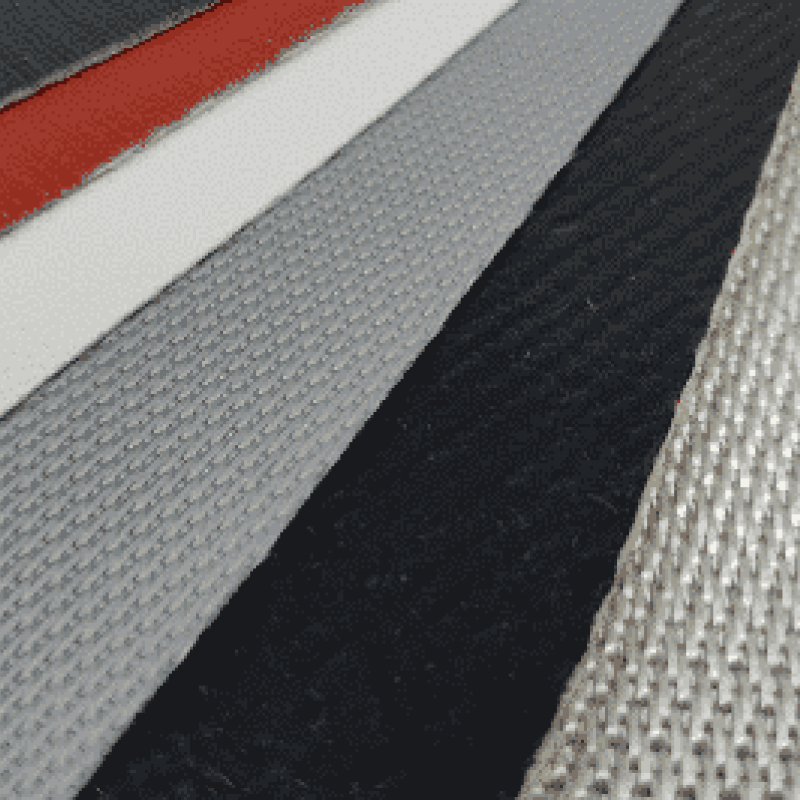

Fabric Types

Which fabric is suitable for a bellows depends on the specified operating conditions and requirements, with temperature and medium being the most important factors in the choice of material:

Tarpaulin: suitable for temperatures up to 70 ° C, is often used as dust protection

Glass fabrics - the "all-rounder" among our fabrics: either with double-sided PU or silicone coating is suitable for a temperature range of 250 - 550 ° C.

Aramid fabric with aluminum coating: suitable for temperatures up to approx. 350 ° C, has a high tensile strength

Silicate fabric with an aluminium coating or vermiculite coating: for temperatures up to approx. 1000°C, often used in steel works and foundries due to its temperature resistance.

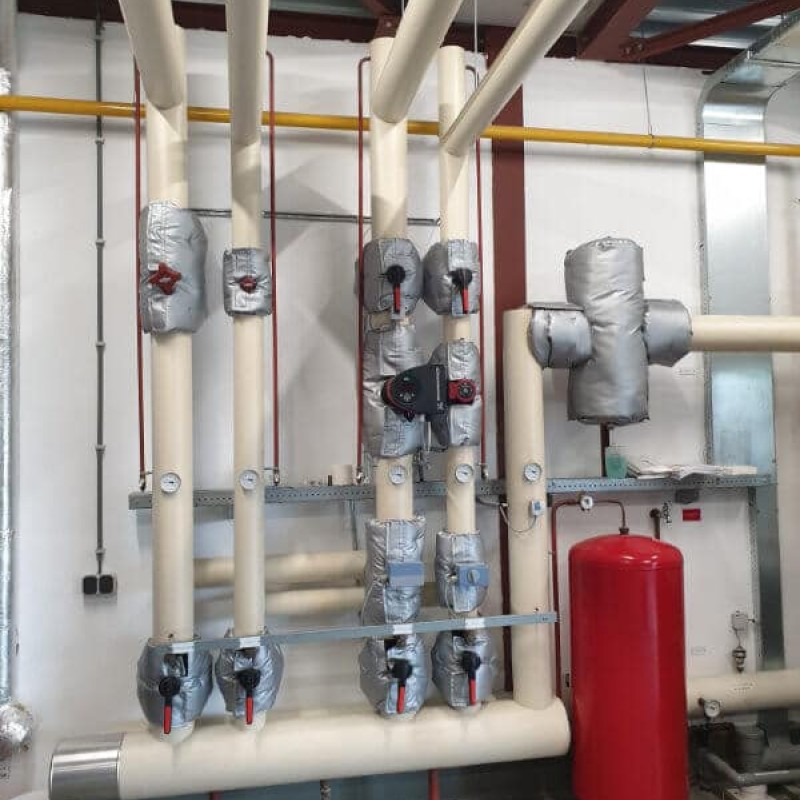

Application

Bellows are mainly used as cover and protection for cardan shafts, piston rods, cylinders, etc. in various industries. Among other things, they protect against all types of contamination (dust, metal and wood chips, etc.), liquids, heat, oils and fats, flying sparks, etc.

Our bellows are specially designed for the high-temperature range and can be used at temperatures up to 1000 ° C. A suitable fabric construction also allows use under aggressive conditions (eg by flue gases).

Bellows by type of manufacture

Annulus bellows: is sewn together from individual, punched or cut circular rings. The ends are cylindrically shaped so that attachment by means of hose binders is possible. A divisible design is not possible with a circular bellows.

Dressier bellows: A cylinder is formed by the installation of wire rings (if necessary also tension springs or pull-out locks) to a bellows. Through the use of divisible wire rings, a skin pass can be easily mounted around the machine part and closed by zipper, Velcro or snaps.

Other kinds: A stretch bellows is made from one piece (not divisible) and fitted with circular steel rings (similar to a dressing bellows). By exploiting the diagonal stretch capacity of the fabric, a good axial range of movement is obtained. Here, too, fastening by means of hose ties is possible. Furthermore, cylinders reinforced with a sealing ring (pouring funnels) in various diameters and lengths, simple covers and (heat protection) curtains, etc. can also be manufactured.Depending on the type of bellows, the following possible designs are available, among others:Divisible by means of zipper, Velcro or snap fasteners (only for skin pass bellows)With / without flange or flange preparationsHoles and bores according to customer specificationsRound, angular or combined shapes

-

RBS Kompensator GmbH

In 2009, at the request of many customers, RBS Kompensator GmbH was founded as the 100% sister company of KS Kneissl & Senn Technologie GmbH under Senn Beteiligungs GmbH.

Building on the existing know-how about temperature-resistant high-performance fabrics, these began to be manufactured as individual pieces in the form of soft-material compensators by hand in Erl. Gradually, various sewing and welding machines were acquired in order to be able to produce all common shapes (round / square / round on square etc.) in the best possible way.

Together with our team we try to live the idea of the "One Stop Shop" and make sometimes impossible things possible according to our motto: "Viribus unitis - with united forces".