Aspen Aerogel ®

The solids in silica aerogels are poor conductors and consist of very small, three-dimensional, intertwined clusters that make up only 3 % of the volume.

- Types

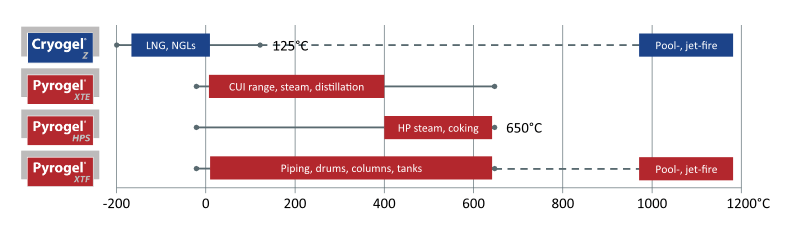

- Pyrogel® HPS | Pyrogel® XTE | Pyrogel® XTF | Cyrogel® Z | Cyrogel® x201

-

Thermal power

Superior thermal performance, savings in logistics.

Reduced thickness

Reduced thickness and profile - Physically robust and impact resistant.

Environmentally safe

Ecologically safe, hydrophobic and yet breathable.

Manufacturer

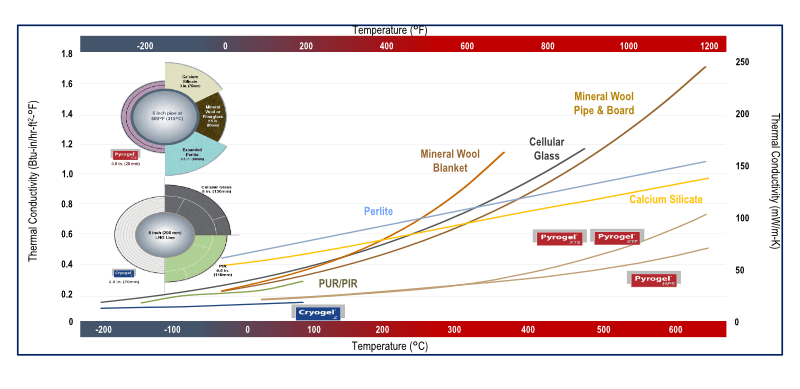

Aspen Aerogels ® is the world's leading manufacturer of airgel blankets and has pioneered the development of this technology in the industrial marketplace since 2001. The Pyrogel® and Cryogel Z® insulation is now widely accepted and adopted as the benchmark standard for airgel technology. Aspen's airgel insulation is up to five times more effective than traditional insulation materials. The materials offer space-saving, easy-to-use solutions over a wide temperature range, making them the most efficient industrial insulation on the market.

Product types

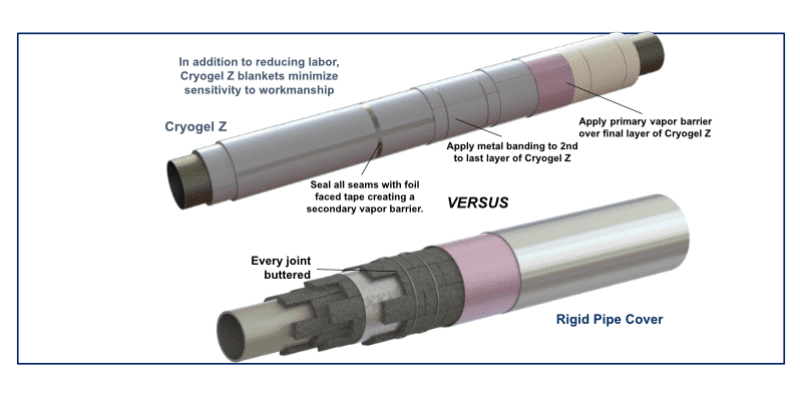

product thickness (mm) Thermal conductivityability (mW / mK) Max. Temp. (° C) application Pyrogel® HPS ASTM C1728 10 22 650 Optimized for high temperature hydrocarbon & chemical processing, steam pipes, vessels and equipment, gas and steam turbines, removable blankets Pyrogel® XTE ASTM C1728 5 10 22 650 CUI defense, medium to high temperature processes, pipes, vessels and equipment, district energy steam networks, Aerospace and defense systems Pyrogel® XTF 10 22 650 Passive pool fire and passive jet fire protection for industrial and commercial applications, relief system sizing (API 521) Cyrogel® Z ASTM C1728 5 10 17 120 Sub-ambient and cryogenic pipelines, vessels and equipment, gas liquefaction & re-gasification facilities Cyrogel® x201 5 10 17 200 Sub-ambient including refrigerated appliances, cold storage and aerospace

About the material

The aerogel part of our high performance insulation blankets is comprised of synthetic amorphous silica (SAS). The other major ingredient in our products is a non-woven, needled batting comprised of either E-glass fibers or a blend of polyester (PET) fibers and E-glass fibers. Synthetic amorphous silica has been produced for more than 100 years for a variety of uses (adsorbents, fillers, anti-caking agents) and consumer products (toothpaste, cosmetics, food, animal feed).

The US EPA recently listed synthetic amorphous silica as a chemical on the Safer Chemical Ingredient List, part of the Safer Choice program. The Safer Chemical Ingredients List (SCIL) is a list of chemical ingredients that the Safer Choice Program has evaluated and determined to be safer than traditional chemical ingredients.

Material development

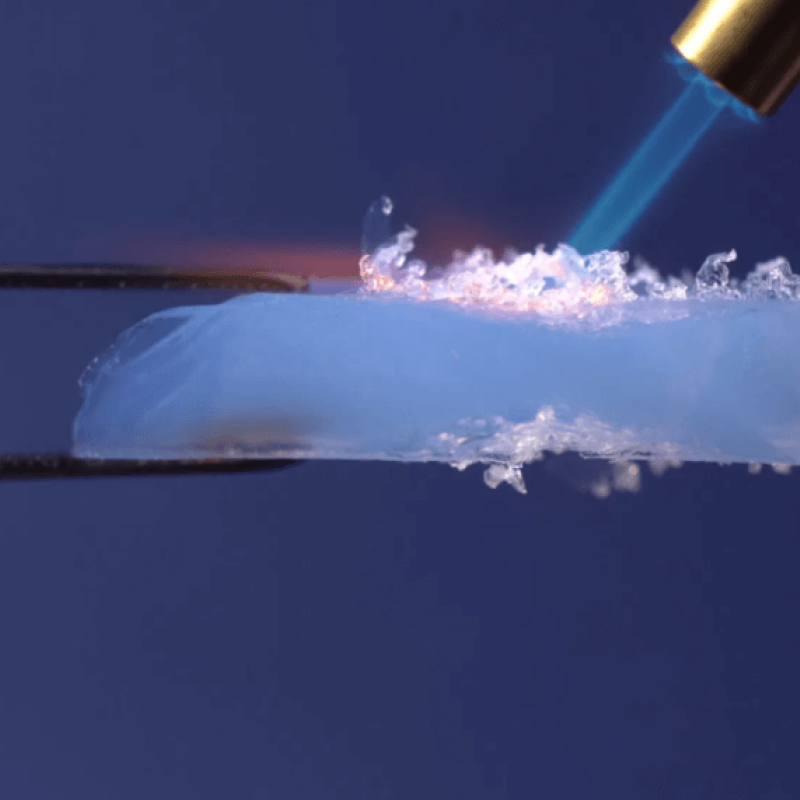

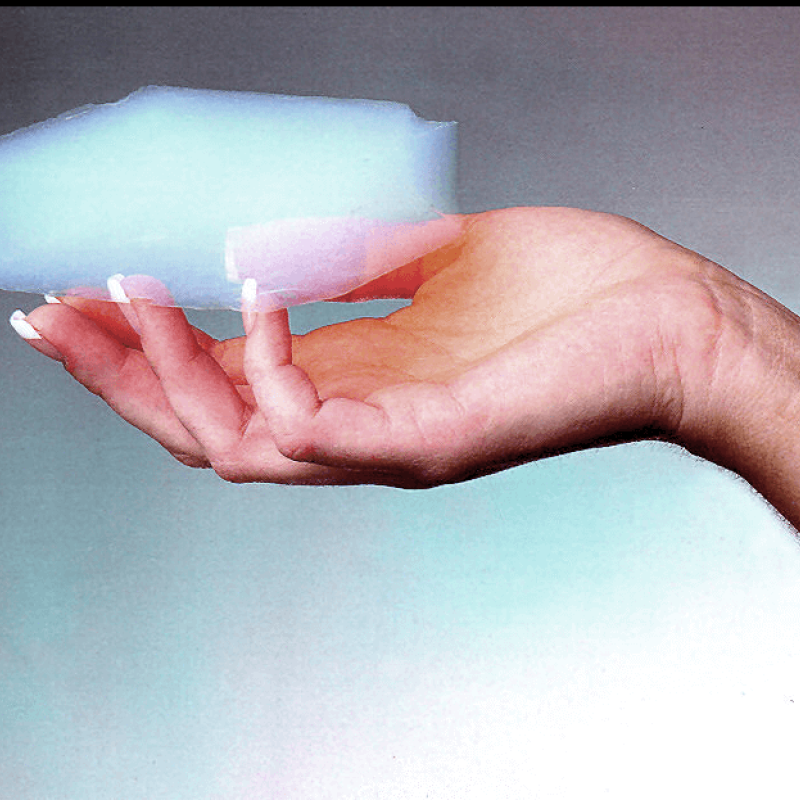

Aerogels have been in existence for more than 80 years. Invented in 1931 by Dr. Samuel Kistler at the College of the Pacific in California, silica aerogel is a lightweight solid derived from gel in which the liquid component of the gel has been replaced with gas. When the liquid is removed, what remains is “puffed-up sand," with up to 99% porosity. The result is an extremely low density solid with several remarkable properties, most notably its effectiveness as a thermal insulator. Aerogels also have value in emerging applications such as energy storage, filtration and carbon capture.

Safety instructions

Synthetic amorphous silica is oleophilic, so it readily absorbs the oils from your skin. This characteristic is why synthetic amorphous silica is used in cosmetics as an anti-sheen agent. For worker comfort when working with Pyrogel®, Cryogel® or Spaceloft®aerogel blanket insulation, we recommend safety eyewear, work gloves, long sleeves, and long-legged work clothes. Respiratory protection is recommended if dust exposures exceed occupational exposure limits. Aerogel dust is easily washed from the skin and clothing using soap and water.

Characteristics

The solids in silica aerogels are poor conductors and consist of very small, three-dimensional, intertwined clusters that make up only 3 % of the volume. The conductivity through the solid is therefore very low. The remaining 97 % of the volume of the aerogels consist of air in extremely small nanopores. The air has little room to move, which hinders both convection and gas phase conduction. These properties make aerogels the lowest density solid and the most effective thermal insulator in the world. After many decades as a laboratory curiosity, Aspen Airogels has successfully developed a technically and economically feasible form of airgel for industrial and building insulation applications.

Benefits

- Superior thermal performance

- Reduced thickness and profile

- Less time and labor for installation

- Reusable - lower lifetime costs

- Physically robust and impact resistant

- Logistics savings - time and money

- Simplified inventory

- Hydrophobic yet breathable

- Environmentally safe

-

Downloads

Datasheet Pyrogel® HPS

Product properties, typical applications and availabilities.

Datasheet Pyrogel® XTE

Product properties, typical applications and availabilities.

Datasheet Pyrogel® XTF

Product properties, typical applications and availabilities.

Datasheet Cyrogel® Z

Product properties, typical applications and availabilities.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.