Silicone foam sheet goods

Our silicone foam sheets offer best quality as continuous rolls or sheets. The products are part of our range of silicone rubber sheets.

- SEAL

- 150 kg/m³ (very soft) up to 530 kg/m³ (solid)

- THICK

- 1.0 mm to 45 mm

- WIDTH

- Up to 1000 mm

-

Temperature resistant

Thermally stable over a wide temperature range -60°C to 230°C (250°C).

Various densities

Various densities from 150 kg/m³ (very soft) to 530 kg/m³ (firm) available.

Damping | Insulation

Can be used as a seal, as damping and insulation or for absorbing tolerances.

CHARACTERISTICS

Our silicone foam sheets offer best quality as continuous rolls or sheets. The products are part of our range of silicone rubber sheets. With a choice of thicknesses from 1.0 mm to 12.5 mm in rolls or up to 45 mm in silicone foam sheets.

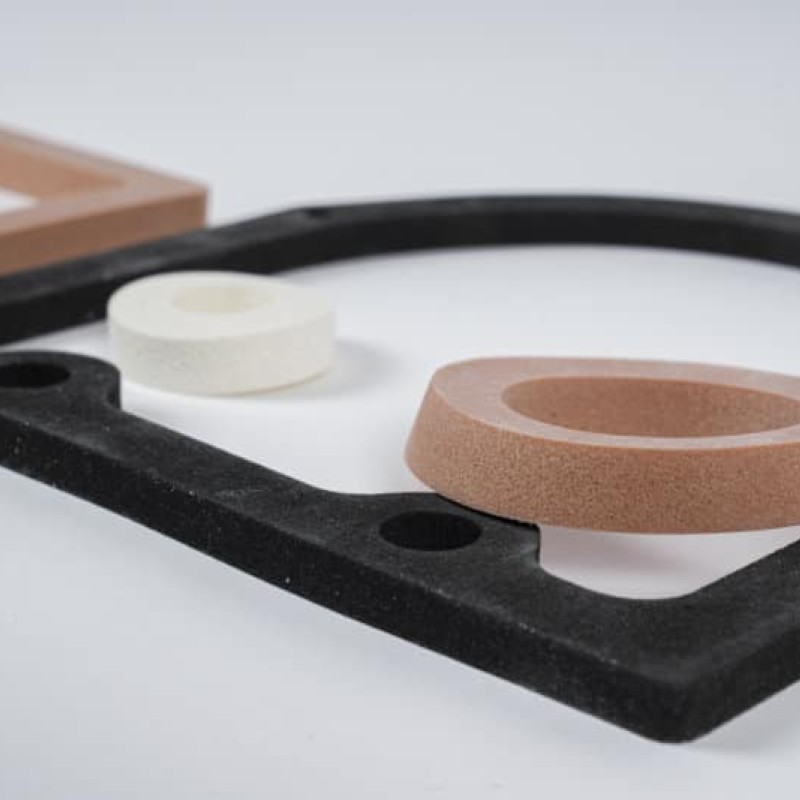

Our silicone foam sheets provide excellent compression properties in the manufacture of gaskets and seals, especially when the sealing surface is not smooth. With a water absorption of <1%, our silicone foam sheets offer excellent sealing properties against water and dust ingress, providing protection for the application. Processed on calendered production lines and controlled by advanced technologies such as back-rolling and cross-cutting equipment, the flatness and width of silicone foam sheets remain consistent to provide a high-quality, smooth surface.

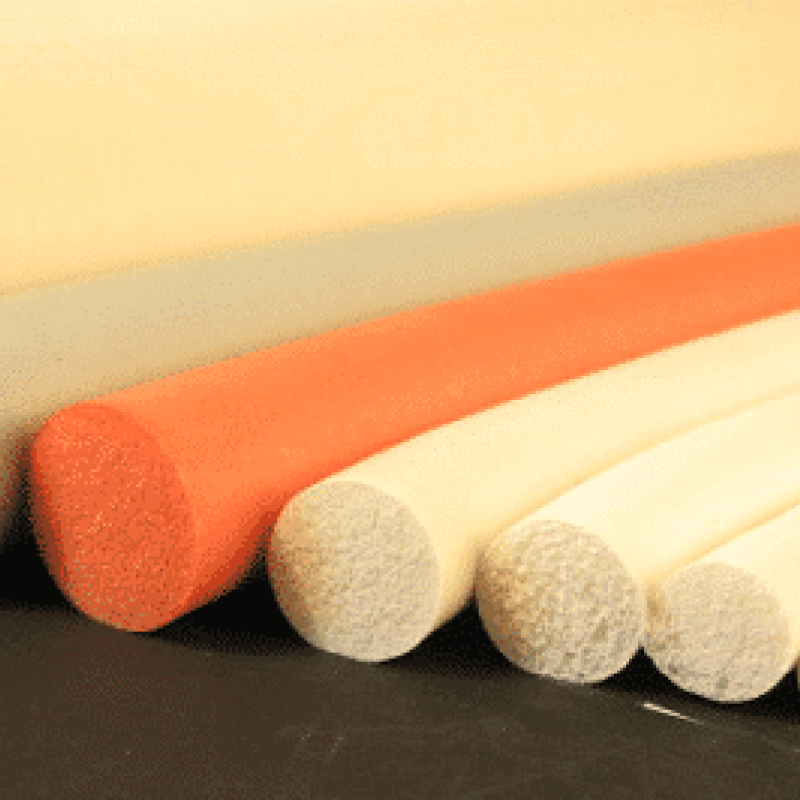

Our silicone foam sheets are available in densities from 150 kg/m³ (very soft) to 530 kg/m³ (firm), widths up to 1000 mm and thicknesses from 1.0 mm up to 45 mm in sheets. The sheets are available as standard in white, red-brown, dark grey or blue with the option of self-adhesion for easier installation. Available in a range of special grades, we can formulate our silicone foam sheeting to suit your application(s).

benefits

- Up to 1000 mm wide

- Closed cell

- Extremely low water absorption (<1%)

- Excellent ozone and UV resistance

- Densities from 150 kg/m³ (very soft) to 530 kg/m³ (firm)

- Available in white, riox and dark grey as standard

- Thermally stable over temperature range -60°C to 230°C (250°C)

- Thicknesses from 1.0 mm to 12.5 mm (rolls) / up to 45 mm (sheets)

- Available in white, red-brown, dark grey or blue

- Version with self-adhesive finish possible

ANWENDUNG

Our silicone foam sheeting has excellent compressive strength and can be used in extreme temperatures. This makes it suitable for many applications, such as

- Gaskets

- Insulation

- Vibration damping

Our silicone foam sheet goods are available in a range of densities from 150 kg/m3 (super soft) to 530 kg/m3 (rigid). Each density can be used for a range of applications, depending on pressure requirements.

The sheets are closed-cell, which means they have extremely low water absorption. This allows the silicone foam to be used as a gasket in many outdoor applications. Seals for HVAC systems, lighting systems and electrical enclosures are just a few applications where minimal water penetration is important.

Open and closed cell silicone foam

OPEN-PORED SILICONE FOAM

Open cell means that each cell, or bubble if you will, is openly connected to the next cell. These cells are not completely sealed, so water, moisture and dust can very easily penetrate the cell structure.

A good example of an open cell silicone foam is the kind of silicone foam you use to wash your car or wash up at home. If you put the silicone foam in a bucket of water, the silicone foam soaks up water, which is then squeezed back out onto the car. The water can penetrate through every cell, so it is absorbed and held in the silicone foam.

CLOSED CELL SILICONE FOAM

Closed-cell silicone foam is what we produce and process at KS Kneissl & Senn Technologie GmbH.

It has a very different cell structure than open cell silicone foam. Each cell in a closed cell silicone foam is a completely enclosed sphere in which the air is trapped. Unlike open cell silicone foam, water, moisture and dust cannot easily penetrate the cell structure because there are no connections between the cells. Closed cell silicone foam is excellent for sealing when water and dust need to be kept out of an application because it absorbs very little water.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.