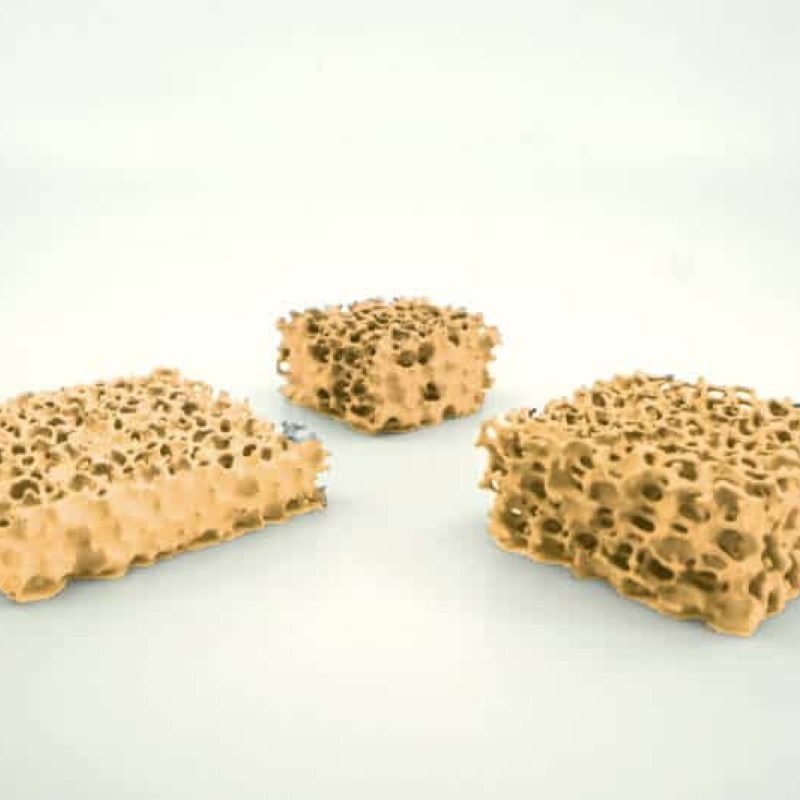

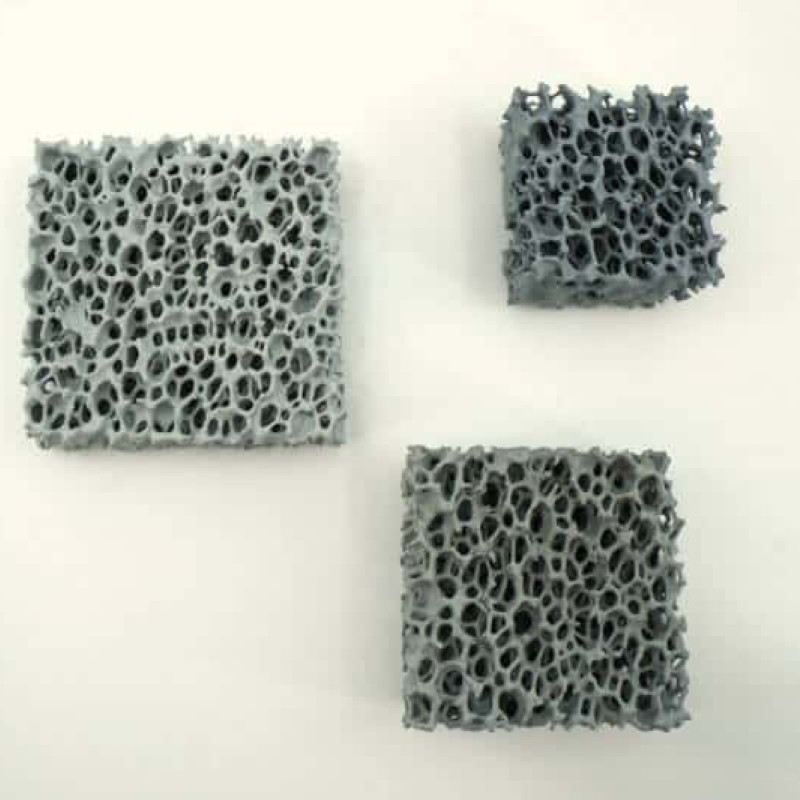

Ceramic foam filters

Foam ceramic filters for max. casting temperatures up to 1450°C in various sizes, thicknesses and materials. The application of ceramic foam filters can be divided into the aluminium foundry sector and the iron, steel and heavy metal foundry sector.

- Type

- AS | Al2O3 | SIC | ZrO2

-

Temperature resistant

High temperature resistance for casting temperatures up to 1700°C.

Various materials

Select the right type for the casting depending on the intended use.

Standardized

Available in various standard sizes and thicknesses.

CHARACTERISTICS

Foam ceramic filters for max. casting temperatures up to 1450°C in various sizes, thicknesses and materials. The application of ceramic foam filters can be divided into the aluminium foundry sector and the iron, steel and heavy metal foundry sector. In our assortment you will find:

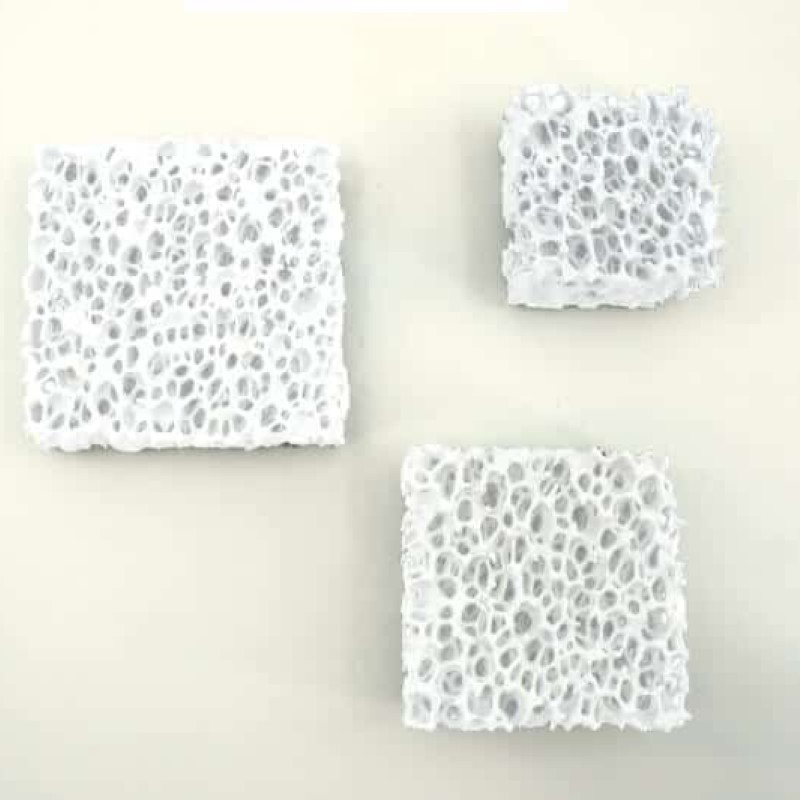

- KS ceramic foam filter AS (up to 820°C) for many aluminium casting alloys

- KS ceramic foam filter Al2O3 (up to 1000°C) for common aluminium castings and wrought alloys as well as pure aluminium

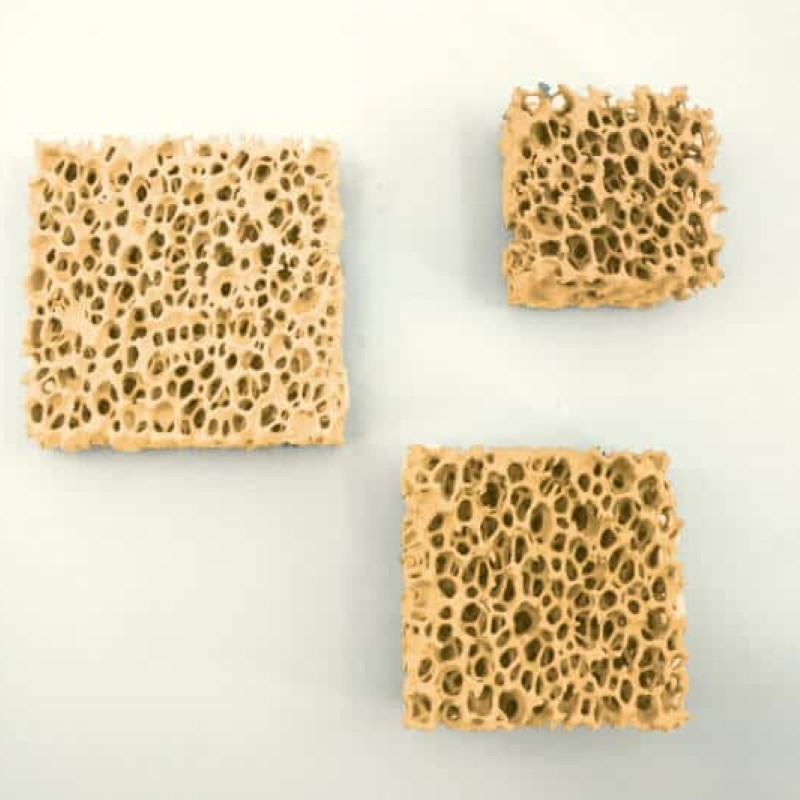

- KS ceramic foam filter SIC (up to 1450°C) for cast iron alloys, copper, bronze and brass alloys as well as aluminium alloys

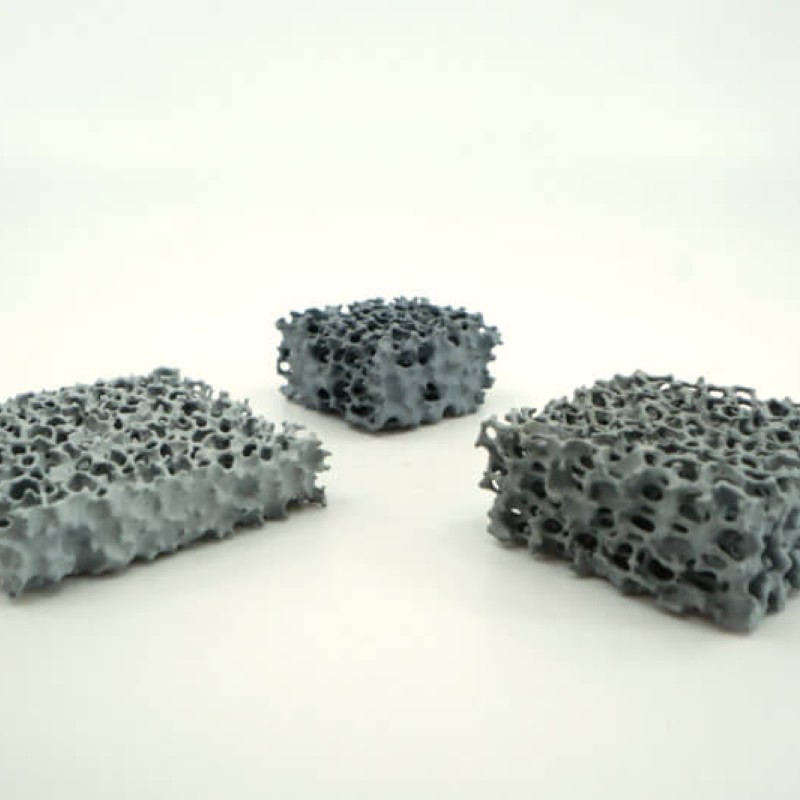

- KS ceramic foam filter ZrO2 (up to 1700°C) for common steel alloys, cobalt and nickel-based alloys as well as iron and magnesium castings

Benefits

- High temperature resistance

- For casting temperatures up to 1700°C

- Available in standard sizes and thicknesses

- Special sizes and thicknesses on request

- Application in aluminium foundries

- Application in iron casting

- Application in cast steel

- Application in heavy metal casting

TECHNICAL DETAILS

AS Al2O3 SIC ZrO2 material Al2O3 SIC, SiO2 bonded ZrO2, partially stabilized with MgO application Cast aluminium alloys Cast aluminium alloys Iron casting alloys Steel alloys Special alloys* Wrought alloys Copper alloys KObalt alloys Pure aluminium Bronze alloys Nickel-base alloys Special alloys* Brass alloys Ferrous alloys Aluminium alloys Cast magnesium Special alloys* Special alloys* Max. Gauge temperature 820°C 1000°C 1450°C 1700°C Temperature resistance Good Good Good Good Three-point bending strength Min. 0,3 mPa Min. 0,5 mPa Min. 0,5 mPa Min. 1,0 mPa Material density 1,9 g/cm3 2,2 g/cm3 1,9 g/cm3 4,6 – 4,8 g/cm3 Coefficient of thermal expansion Approx. 7,6 * 106 K1 Approx. 8,5 * 106 K1 Porosity PPI 10 *Depending on filter dimensions, filters may also be available in PPI 20, 30, 40 and 50. Standard sizes Round: D40 | D50 | D60 | D70 | D75 | D90 | D100 | D125 Square: 40×40 | 50×50 | 55×55 | 75×50 | 75×75 | 100×50 | 100×75 | 100×100 | 125×125 | 150×150 *Other filter sizes, conical filters, special sizes etc. are available on request. All above dimensions are in millimeters. Standard thicknesses 22 mm *Special thicknesses are available upon request. Note: not every filter size is available in every thickness. -

Downloads

Data sheet KS Foam Ceramic Filter AS

Product properties, typical applications and availabilities.

Data sheet KS ceramic foam filter Al2O3

Current product catalog from KS Kneissl & Senn Technologie GmbH.

Data sheet KS foam ceramic filter SIC

Product properties, typical applications and availabilities.

Data sheet KS ceramic foam filter Zro2

Current product catalog from KS Kneissl & Senn Technologie GmbH.

Catalog KS Kneissl & Senn Technologie GmbH

Current product catalog from KS Kneissl & Senn Technologie GmbH.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.