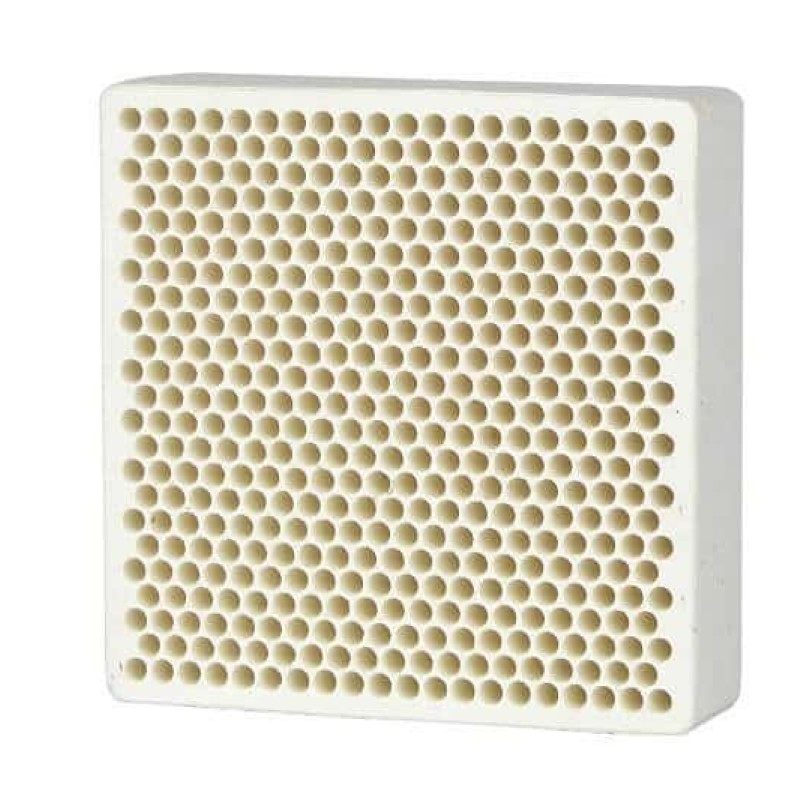

Ceramic round hole filter

Round hole filters made of aluminium silicate ceramic with mullite as the main component are used for casting aluminium and its alloys as well as for iron casting.

-

Defined holes

Holes clearly defined and positioned, clear quality control.

Casting behaviour

Consistent casting behaviour guaranteed by low tolerances.

Foreign particle free

Inside no disturbing foreign particles and impurities.

CHARACTERISTICS

Round hole filters made of aluminium silicate ceramic with mullite as the main component are used for casting aluminium and its alloys as well as for iron casting. Higher quality filters made of corundum-mullite ceramics with an aluminium oxide content of over 70 % are the right choice for steel casting and are widely used. In our range you will find pressed ceramic round hole filters with round, rectangular and square outer contours. The filters are characterised in particular by their precise geometry, which thus ensures optimum flow results, and by their particularly high temperature resistance of up to 1700 °C. Depending on the flow rate, casting speed and filtration capacity, a variety of types are available.

Filters are always installed as close as possible to the casting after the sprue system and before the gate. The resulting laminar flow is important for high quality cast products. Ideally, the filter is installed vertically in a horizontal duct. A reservoir is formed in front of the filter, which is used to absorb the impurities and to homogenize the material and the temperature.

Benefits

- Holes clearly defined, positioned

- Clearly measurable for quality control

- Low tolerances

- Consistent casting behaviour guaranteed

- Straight holes

- Laminar flow

- No interfering foreign particles inside

- Clean (free of dust and particles) and free of impurities

- High dimensional stability

- Smooth surface

- Closed outer contour

- The production takes into account the environment

-

Downloads

Catalog KS Kneissl & Senn Technologie GmbH

Current product catalog from KS Kneissl & Senn Technologie GmbH.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.