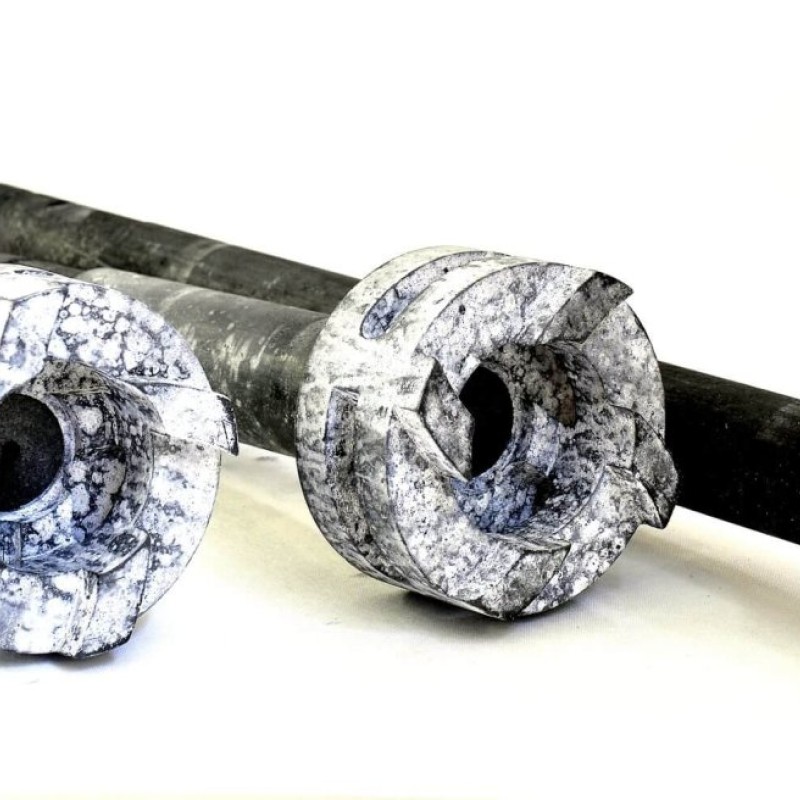

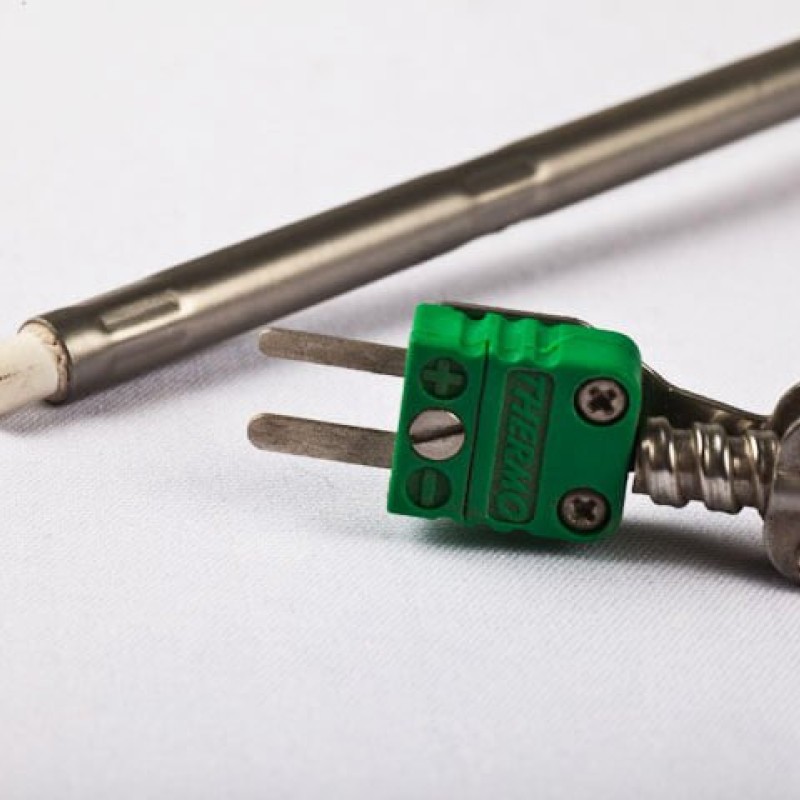

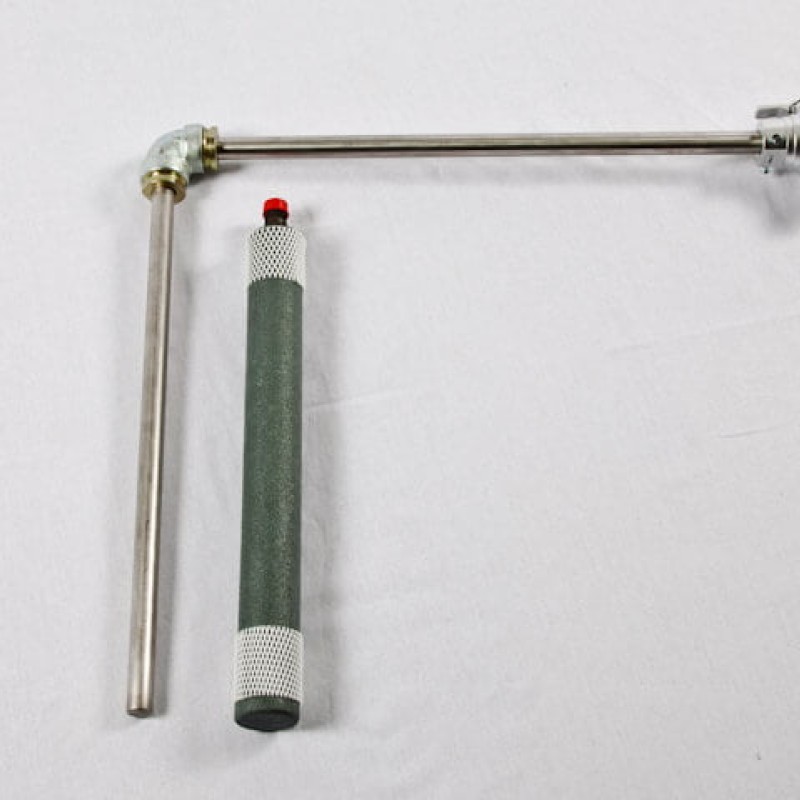

Blower powder (exothermic)

The cavity powders specially developed for the aluminum industry are available ready-to-use and are applied over the entire area of the feeder (s) after the liquid metal has been poured.

-

Aluminium casting industry

Specially developed for the aluminium industry.

Ready to use

Lunker powder is provided ready for use.

Various advantages

From application, to effectively increase the replenishment effect, etc..

CHARACTERISTICS

The cavity powders specially developed for the aluminum industry are available ready-to-use and are applied over the entire area of the feeder (s) after the liquid metal has been poured. The fine powder ignites automatically, then slowly burns off with the release of heat and ultimately forms a solid crust.

For application to risers in sand casting for all alloys to effectively increase the riser effect. Blowhole powders are used to cover and insulate the exposed feeder surfaces in open feeders. They also reduce the rate of cooling of the metal in the risers by exothermic reactions. This can ensure that the feeder solidifies last and that there is always sufficient liquid metal for refeeding. Sprue hoppers can also be heated exothermically for the purpose of refeeding.

Benefits

- Specially developed for the aluminium industry

- Available ready for use

- Ignites independently, burns slowly

- Images a solid crust

- For application on risers and sand casting for alloys

- To effectively increase the make-up effect

- For covering and insulating the feeder surfaces

- Reduce the cooling rate of the metal

-

Downloads

Catalog KS Kneissl & Senn Technologie GmbH

Current product catalog from KS Kneissl & Senn Technologie GmbH.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.