Dichtol products | Polymers

Impregnating and sealing castings: targeted, economical, durable. Reliably seal micropores, porosities and hairline cracks: Significantly reduce scrap and faulty production. With efficient material use and simple application.

-

Impregnation system

Mature ready-to-use polymer impregnation system.

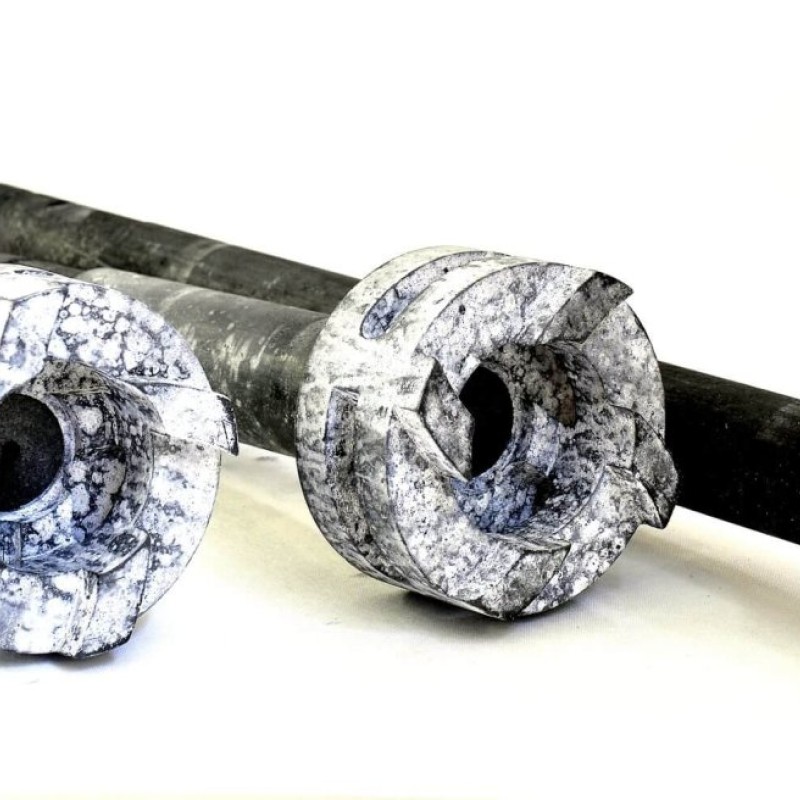

Castings, metal, etc.

Targeted use on castings, metals and raid prototyping components.

Various advantages

Significantly reduce rejects and misproductions, etc.

Properties

Impregnating and sealing castings: targeted, economical, durable. Reliably seal micropores, porosities and hairline cracks: Significantly reduce scrap and faulty production. With efficient material use and simple application.

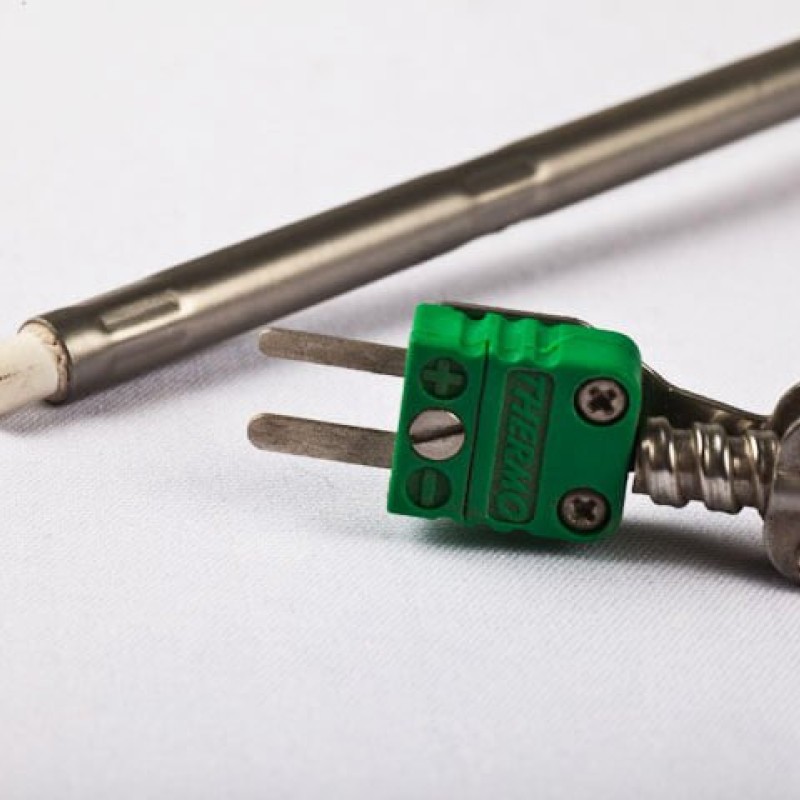

DIAMANT Dichtol is the mature, ready-to-use polymer impregnation system for targeted use on cast parts, metals and raid prototyping components.

Advantages

- Mature ready-to-use polymer impregnation system

- Impregnate and seal castings

- Targeted

- Economic

- Consistent

- For targeted use on castings, metals and raid prototyping components

- Securely seal micropores, porosities and hairline cracks

- Significantly reduce rejects and faulty production

- With efficient use of materials and simple application

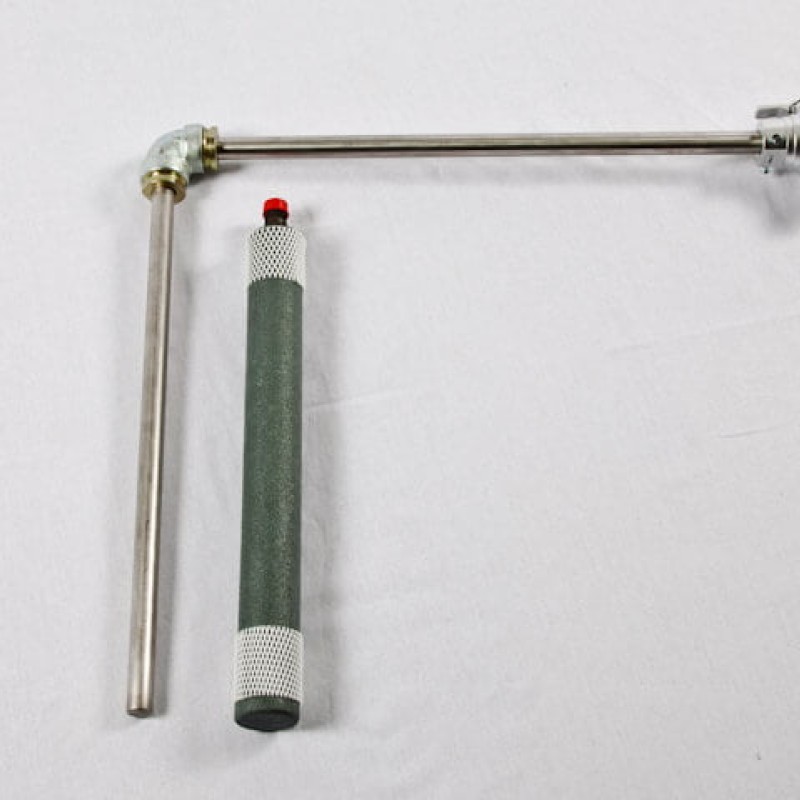

Sealing oil for foundry

Product name Product Description Technical data sheet HTR #0977 Temperature resistant up to 500 ° C, very good penetration behavior WF 49 #1849 Resistant to solvents and aggressive media WFT Standard #1532 All-rounder up to 300 ° C, very good Penetration behavior even with small pores WFT Standard Spray #2087 All-rounder in practical terms 500ml spray can WFT Macro #1546 All-rounder up to 300 ° C for larger pores WFT Macro Spray #2088 All-rounder for larger pores in the 500ml spray can HTWG Hydro #2506 High temperature sealer up to 700 ° C Water-based HTWG S #2505 High temperature sealer up to 700 ° C solvent based Polymer systems

In addition to Dichtol, we carry the following other polymer systems from DIAMANT Metallplastic for:

- superficial corrections (Liquid metal)

- fine and medium-sized repairs (plasticmetal)

- extensive repairs (Ultra metal)

- the capillary metal impregnation (Dichtol)

- the wear protection (RepaCoat)

For a better overview you can download the Product catalog download.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.