Stirrer

Stirrers and accessories for foundry supplies.

At KS Kneissl & Senn we have an extensive stock of various stirrers and accessories for foundry needs.

-

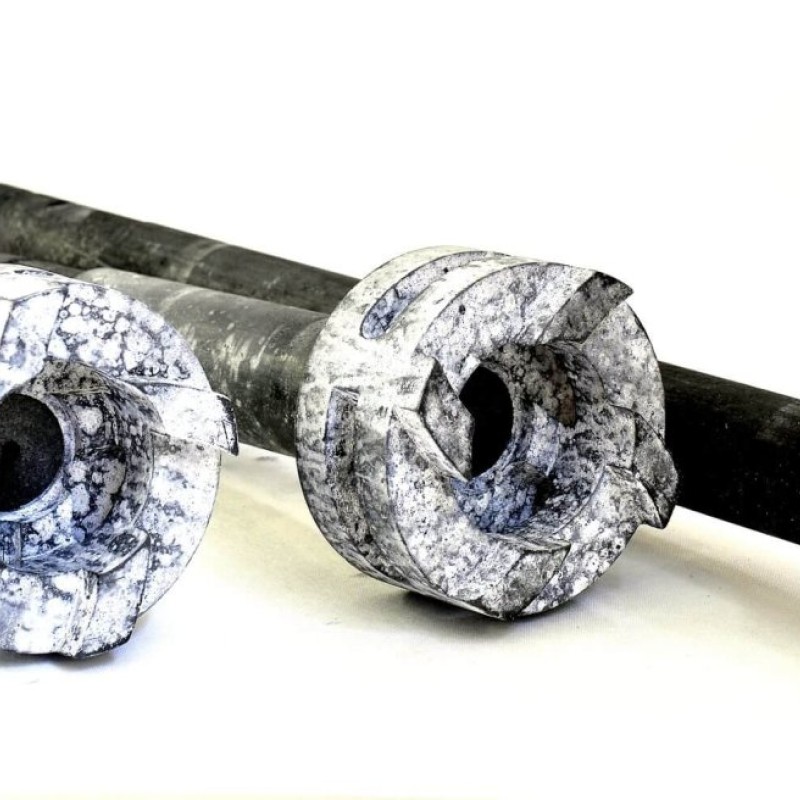

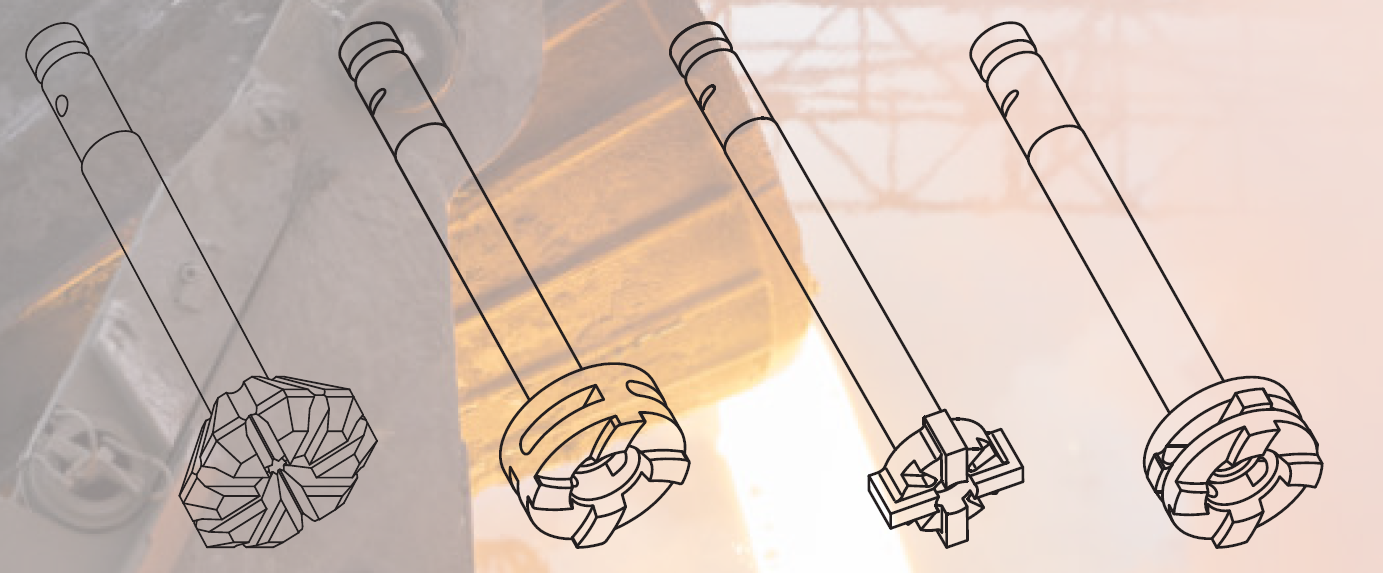

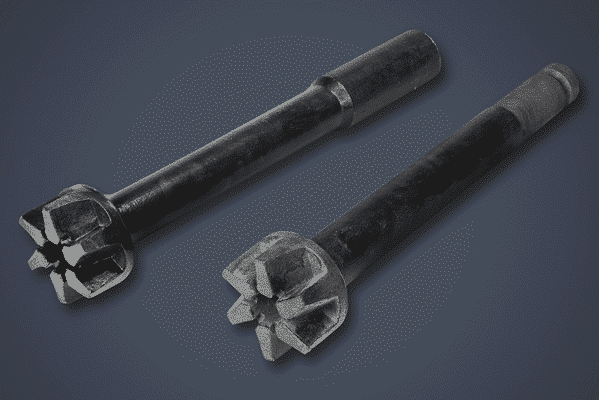

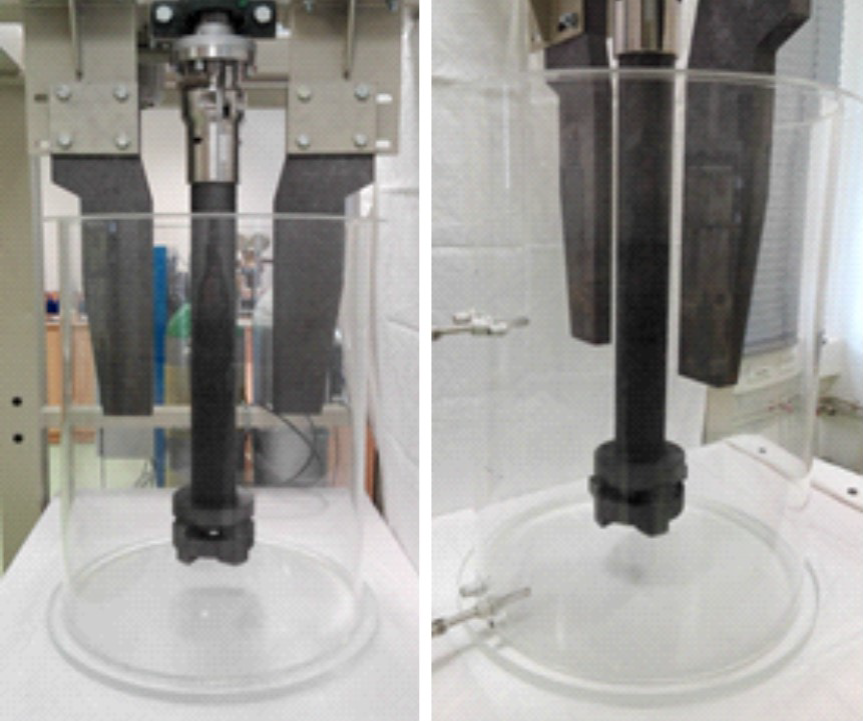

Impeller

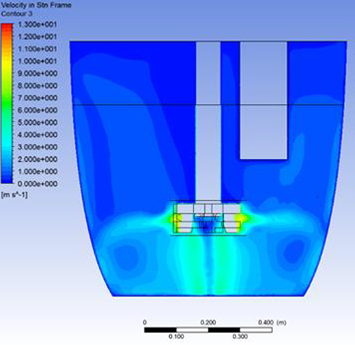

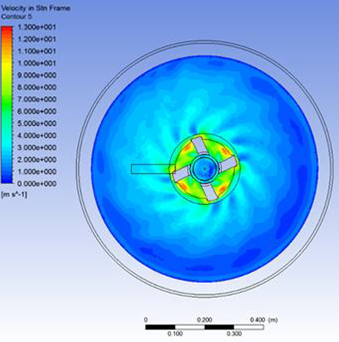

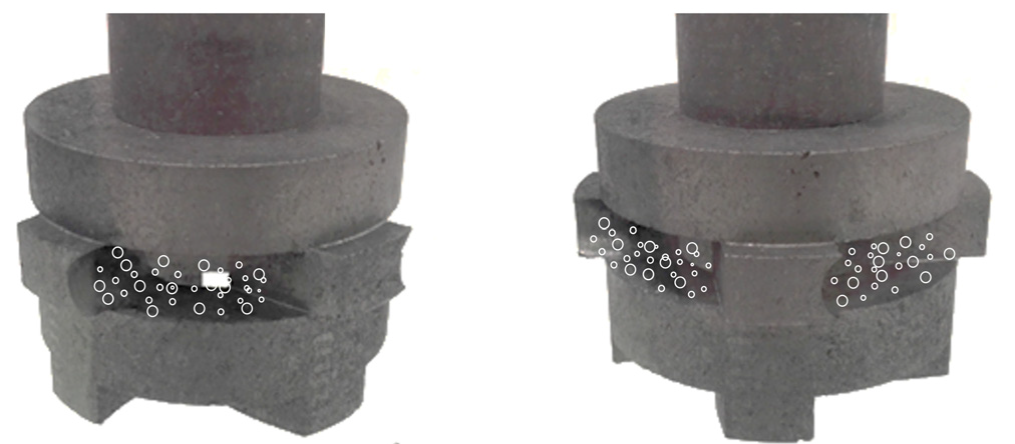

- Rotor form adaptable to your specific application

- Best possible vertical and horizontal gas distribution over the entire ladle

- Control of surface movement by adapting the rotor shape

- Antioxidant impregnation for longer service life

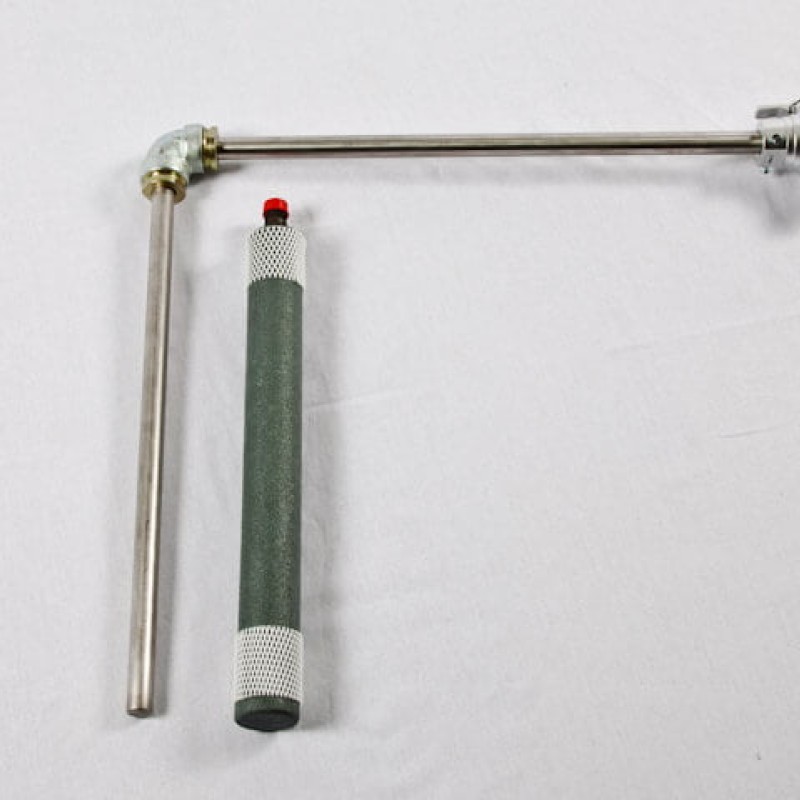

Shafts

- Customized end piece, adapted for each receptacle / socket

- Antioxidant impregnation for longer service life

- Optimized wall thickness and shaft geometry

- Perfect axiality, thus lowest unbalance

Wide range of products

Wide range of stirrers and accessories for foundry needs.

Qualities

Various designs and qualities available.

Experienced advice

Through our many years of experience, we offer the best advice.

Antioxidant impregnation

- Complete penetration of the volume by vacuum technology

- Porous graphite is sealed by crystalline impregnate

- Increase in service life by 10-30% depending on application compared to non-impregnated graphite

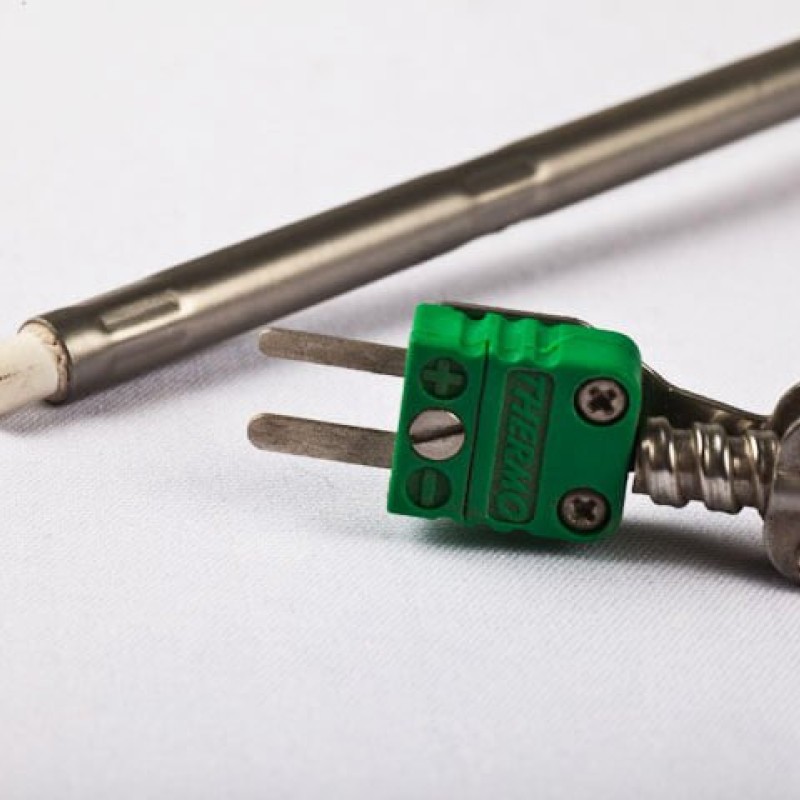

Other consumer goods

- Degassing lances up to 3500 mm

- Channels

- EDM graphite

Technical support

- Integral part of the sale of graphite consumables

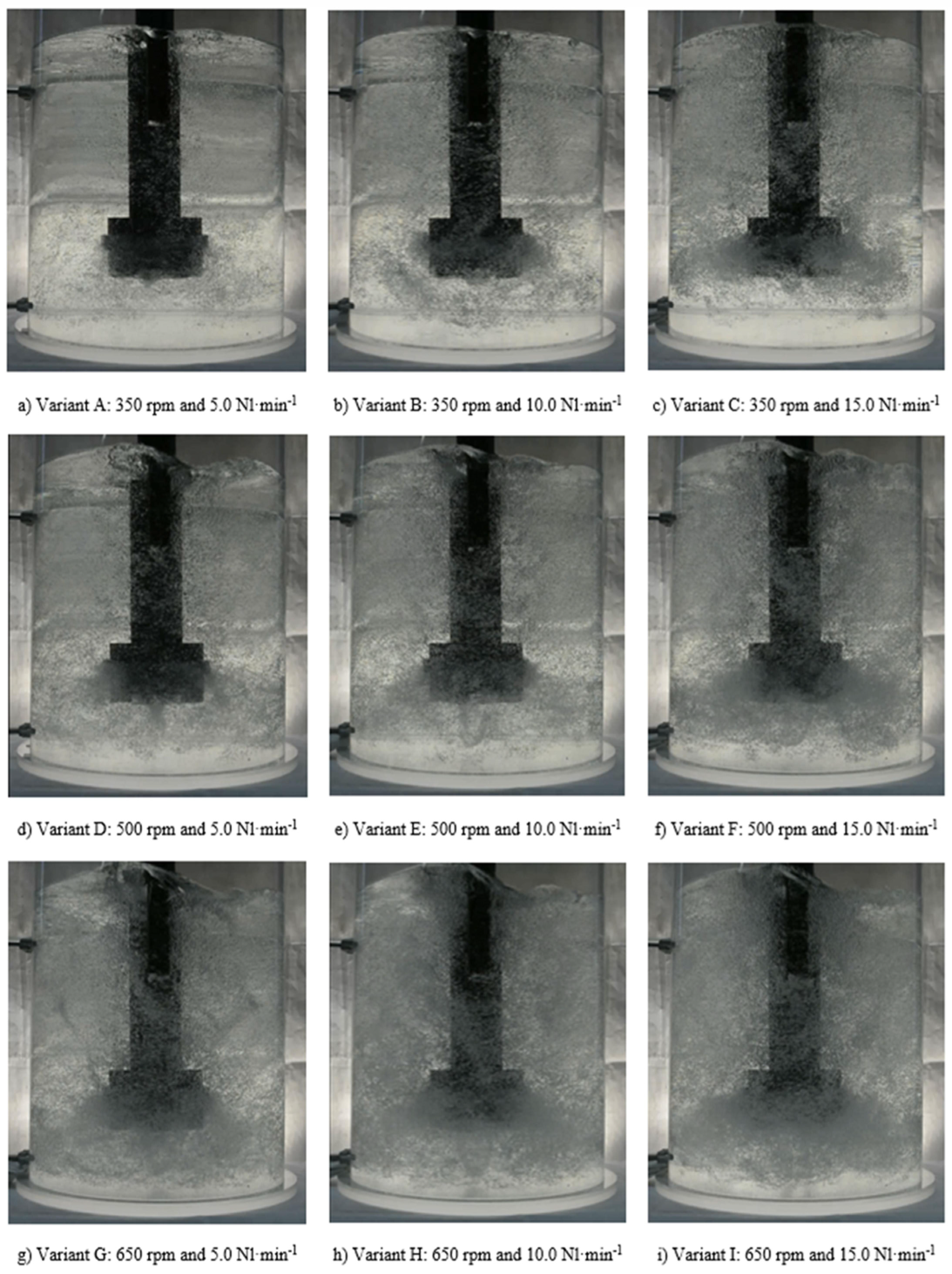

- Setting parameters for the preparation process

- Optimization of rotor design

- Recommendation of suitable graphite grades for various applications

Customized solutions

- Production of graphite products according to specific customer drawing

- Execution in different graphite qualities possible depending on the application

-

Downloads

Catalog KS Kneissl & Senn Technologie GmbH

Current product catalog from KS Kneissl & Senn Technologie GmbH.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.