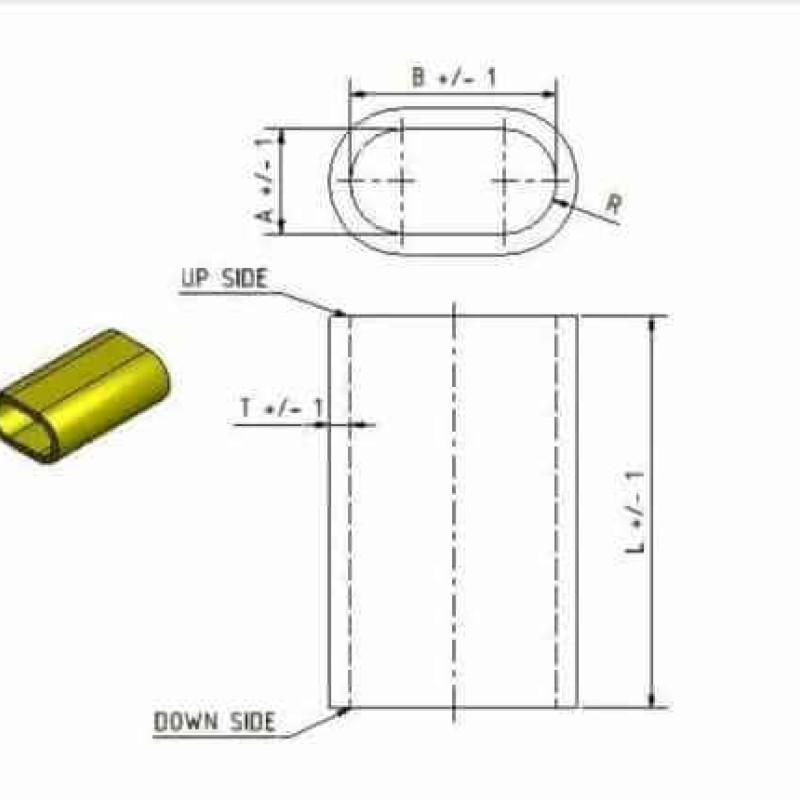

Oval insulating feeders

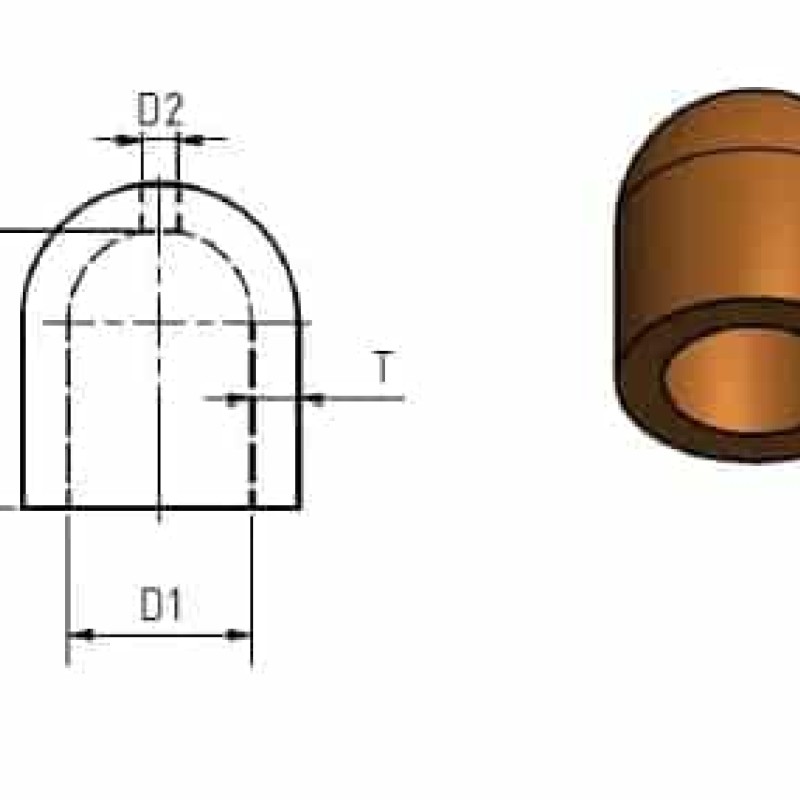

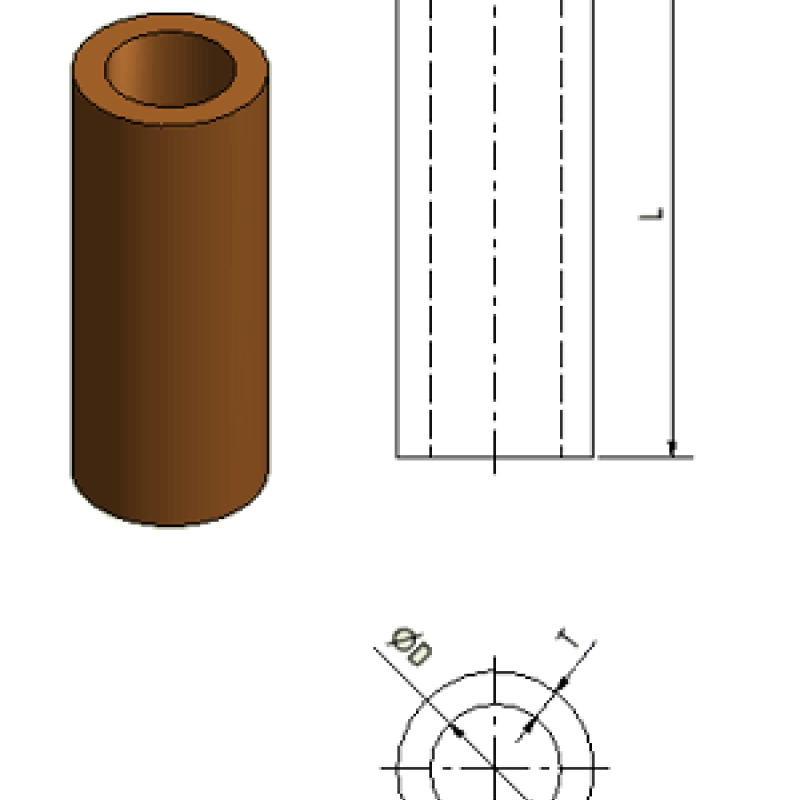

KS round insulating feeders (OO) made of mineral fiber are characterized by high strength and great dimensional accuracy in the internal diameters.

- Diameter (A)

- 25 | 35 | 40 | 50 | 55 | 60 | 70 | 80 | 100

- Width x length (W x L)

- 60 x 150 | 60 x 300 | 75 x 300 | 80 x 150 | 80 x 200 | 80 x 300 | 80R140x150 | 90 x 300 | 101 x 150 | 120 x 150 | 120 x 200 | 120R140x150 | 125 x 300 | 130 x 150 | 140 x 150 | 145 x 150 | 145 x 150BK | 145R140x150 | 160 x 150 | 160 x 180 | 200 x 250 | 200 x 250GDV | 245 x 300

-

Aluminum sand casting

Suitable for aluminum sand casting.

Up to 800 ° C

Resistant up to 800 ° C.

Unclassified

Unclassified material.

CHARACTERISTICS

KS round insulating feeders (OO) made of mineral fiber are characterized by high strength and great dimensional accuracy in the internal diameters. Compared to natural feeders, with a wall thickness of 8mm you have a setting time that is 2.2 - 2.4 times longer. The use of harmless mineral fibers means that no special measures need to be taken with regard to occupational safety. Various shapes and standard sizes are available from stock for every application.

Benefits

- Suitable for aluminum sand casting

- Resistant up to 800 ° C

- Unclassified material

- High strength and great dimensional accuracy

- Longer setting time

- Use of harmless mineral fibers

- Different shapes and standard sizes

-

Downloads

Catalog KS Kneissl & Senn Technologie GmbH

Current product catalog from KS Kneissl & Senn Technologie GmbH.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.