Chesterton mechanical seals

are the product of choice when reliability matters. These products are proven, rugged performers in a wide variety of sealing applications in a variety of industries.

- Product type

- 2810 | 1810 | 442PR | 442™C

-

Cost efficient

Reduced operating costs and optimized inventory management.

Reliable

Increased reliability through advanced technology.

RFID technology

Easy seal identification with RFID technology.

CHARACTERISTICS

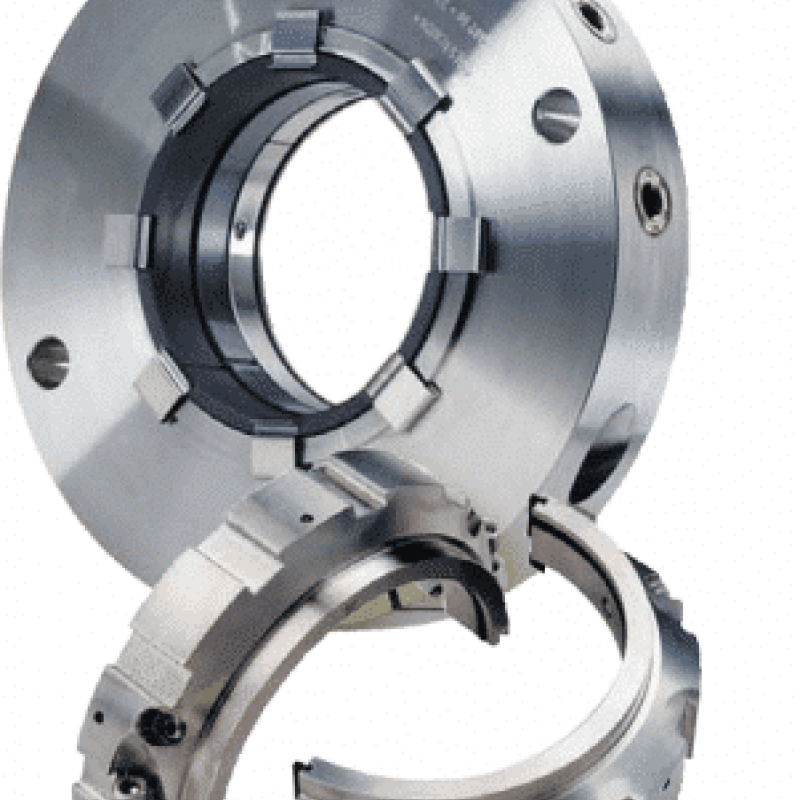

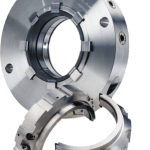

Chesterton mechanical seals are the product of choice when reliability matters. These products are proven, rugged performers in a wide variety of sealing applications in a variety of industries. Cartridge seals are ideal for plant-wide standardization and save time with easy installation. Chesterton's cartridge seal offering includes exclusive, patented features such as self-centering retaining rings and adjustable gland lugs.

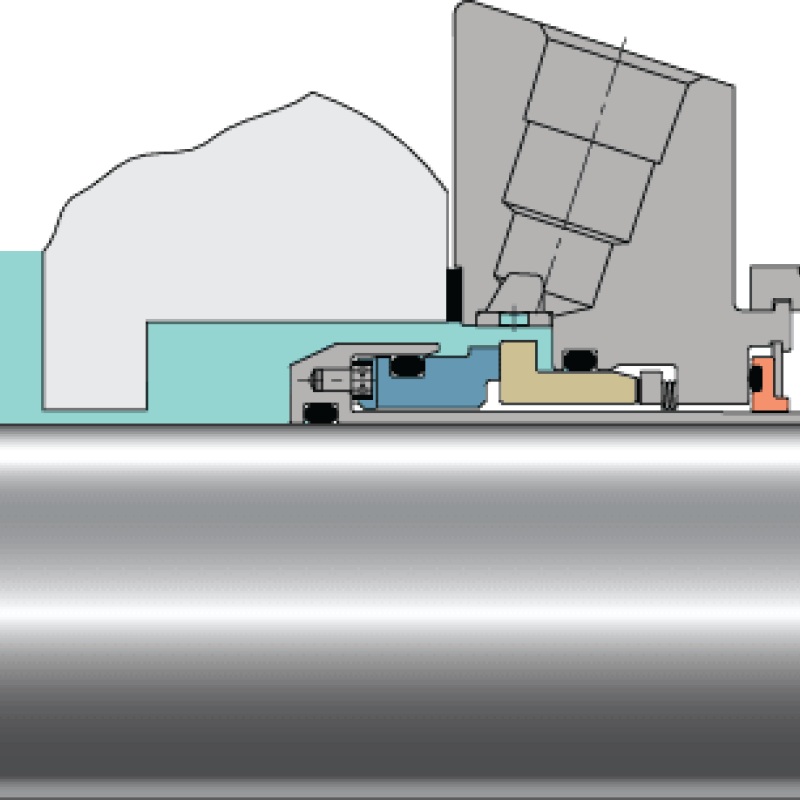

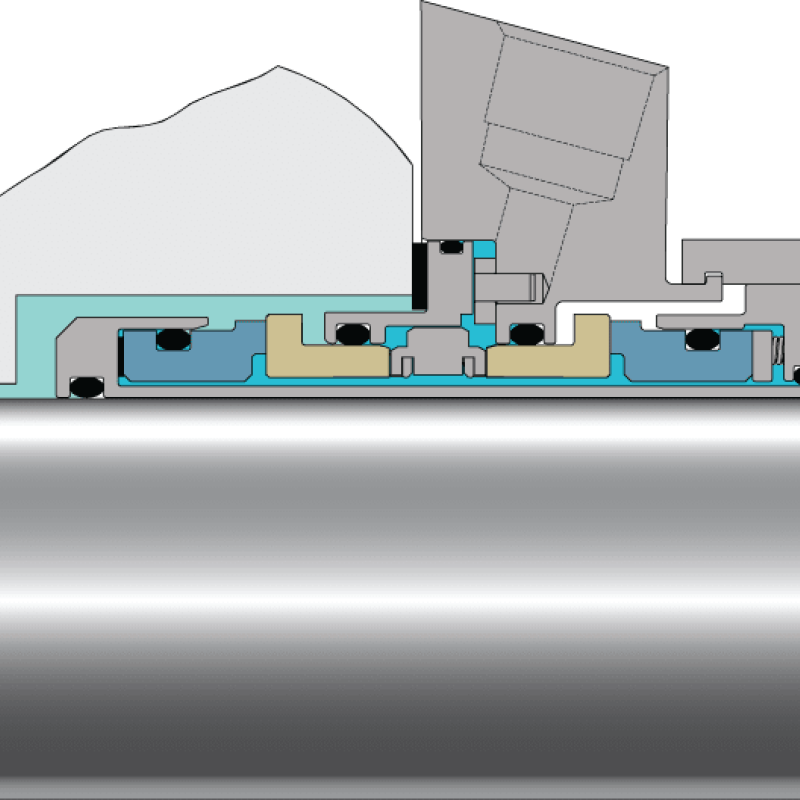

In our range you will find the following mechanical seals: 2810 Robust Modular Double Acting Cartridge Mechanical Seal (GLRD), 1810 Robust Modular Cartridge Mechanical Seal (GLRD), 442PR Split Mechanical Seal (GLRD) with pump ring and 442™C Split Cartridge Mechanical Seal (GLRD).

Benefits

- Reduced operating costs

- Increased reliability

- Easy seal identification with RFID technology

- Optimized warehousing

- Advanced technology - easy to install/operate

- Innovative design with excellent performance

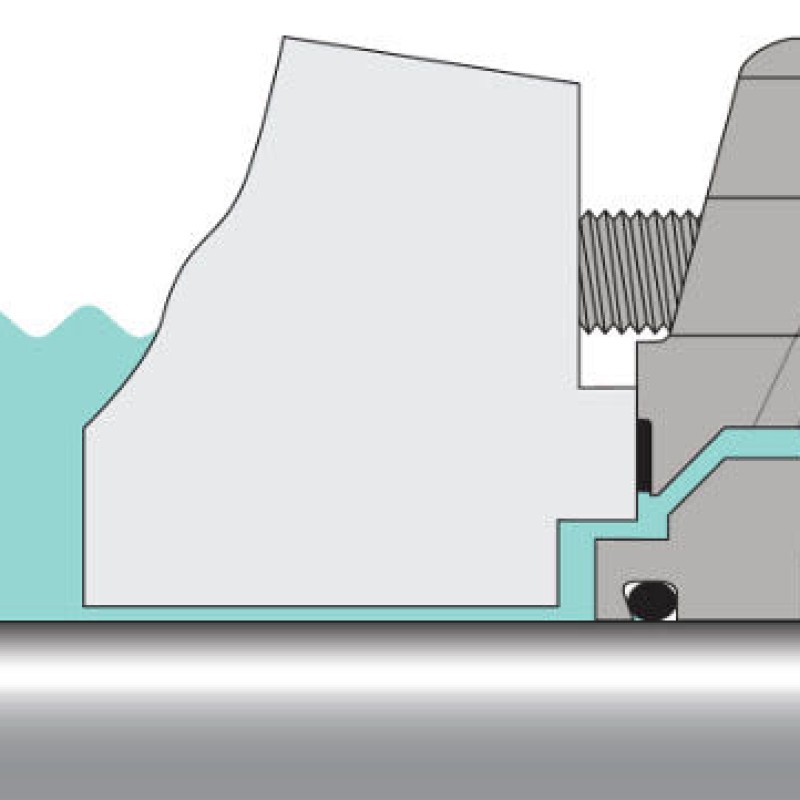

- 2810 Robust modular double-acting cartridge mechanical seal (GLRD)

- 1810 Robust modular cartridge mechanical seal (GLRD)

- 442PR Split mechanical seal (GLRD) with pump ring

- 442™C Split cartridge mechanical seal (GLRD)

-

Downloads

Data Sheet Chesterton Mechanical Seal 2810

Product properties, typical applications and availabilities.

Chesterton Mechanical Seal 1810 Data Sheet

Product properties, typical applications and availabilities.

Chesterton Mechanical Seal 442C Data Sheet

Product properties, typical applications and availabilities.

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.