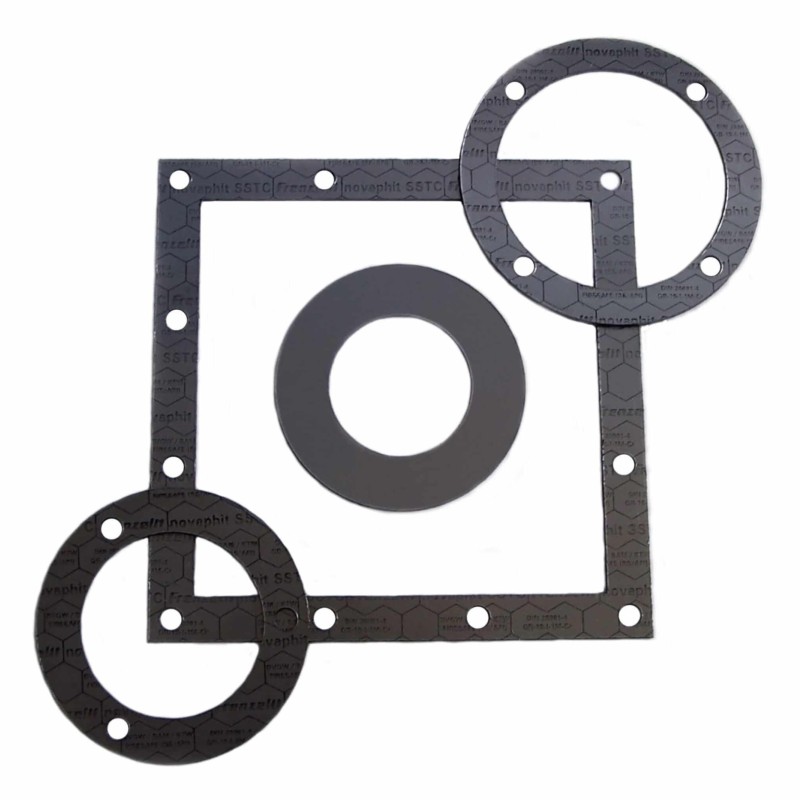

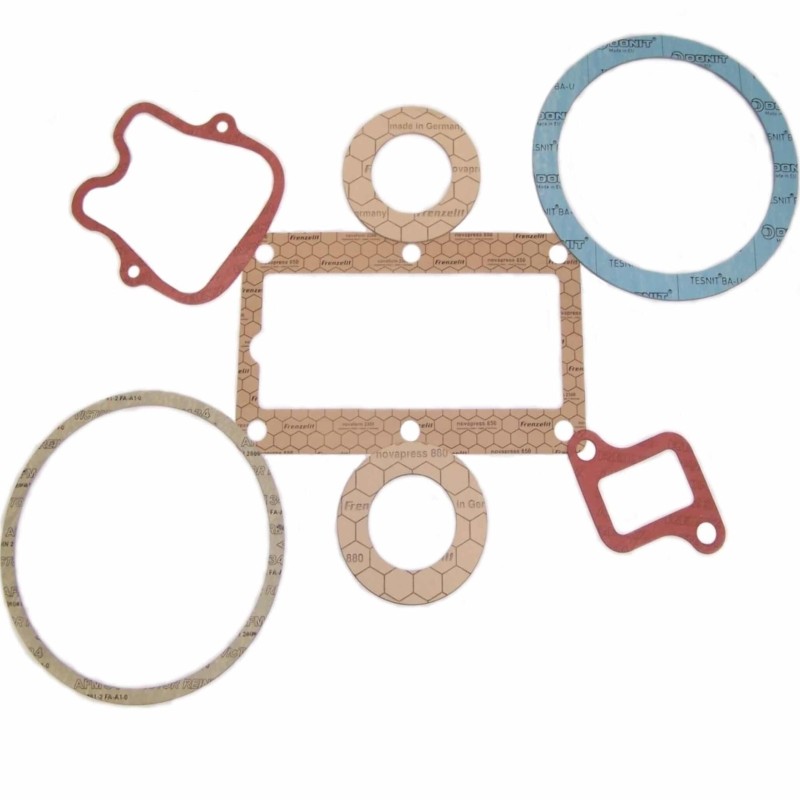

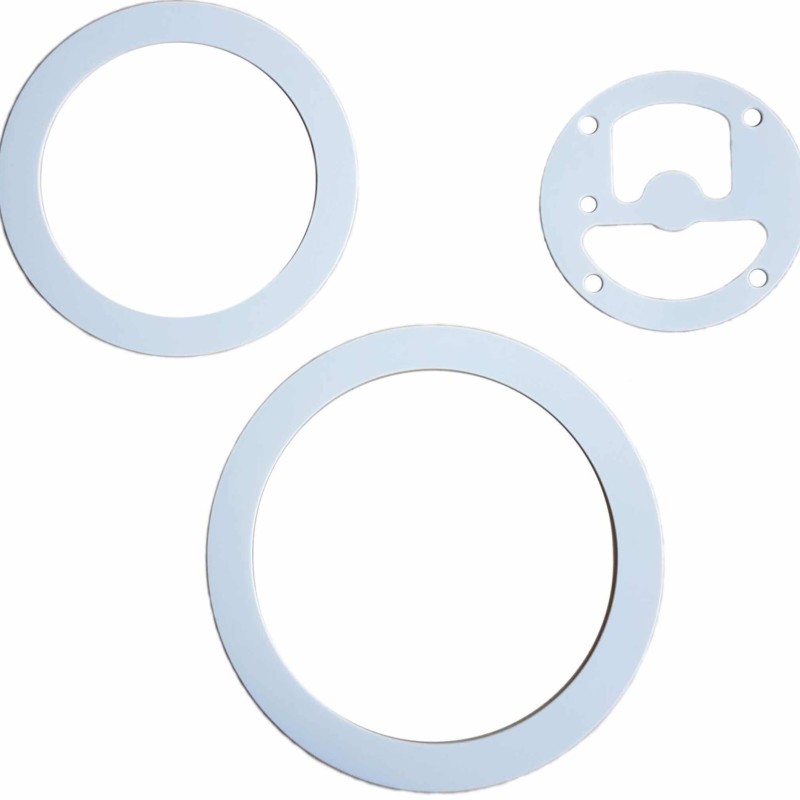

Sealing plates

We supply gasket plates in various materials and sizes. In our range you will find both Frenzelit and Klinger gaskets.

- Type

- Faser-Elastomergebunden | Graphit | Faserverstärkter Graphit | PTFE | Phlogopit-Glimmer

- Variante

- Novapress® | Klingersil® | Klinger® Quantum | Klinger® Top-Sil ML1 | Klinger® Compensil | Novaphit® | Klinger® Graphit Laminat | Novatec® | Klinger® Top-Graph | Novaflon® | Klinger® Top-Chem | Klinger® Soft-Chem | Novamica® | Klinger® Milam PSS

-

Standard applications

Cover almost all standard applications in the field of flat gaskets.

Temperature resistant

Depending on type, temperature resistance from - 210°C to 550°C.

Klinger & Frenzelit

Sealing sheets from the renowned manufacturers Frenzelit and Klinger.

CHARACTERISTICS

We supply gasket plates in various materials and sizes. In our range you will find both Frenzelit and Klinger gaskets. Both represent the latest state of the art in sealing sheets. We supply elastomer-bonded fibre gasket sheets (Novapress®, Klingersil®, Klinger® Quantum, Klinger® Top-Sil ML1, Klinger® Compensil), graphite gasket sheets (Novaphit®, Klinger® Graphite Laminate) as sheet goods, fibre-reinforced graphite sealing sheets (Novatec®, Klinger® Top-Graph), PTFE sealing sheets (Novaflon®, Klinger® Top-Chem, Klinger® Soft-Chem) as well as Pflogopit mica sealing sheets (Novamice®, Klinger® Milam PSS).

We supply the sealing plates in various thicknesses and sizes.

Benefits

- Classic in the flat gasket sector

- Covers almost all standard applications

- Each product type special properties

- Temperature resistance from - 210°C to 550°C

- Sealing sheets from Frenzelit

- Sealing plates from Klinger

-

Downloads

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.