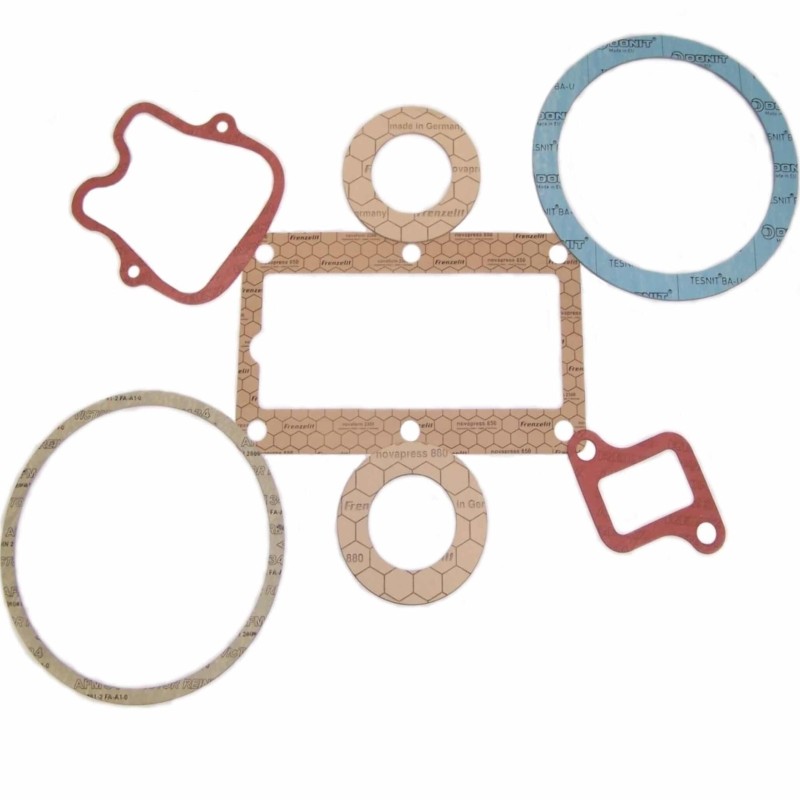

Seals made of phlogopite mica

Phlogopite mica gaskets are based on high-quality, refined phlogopite mica, which is far superior to other types of mica in terms of temperature resistance.

- Type

- Frenzelit Novamica® | Klinger®

- Variante

- Thermex | 200 | 100 Reel | Milam PSS

-

Temperature resistant

Extremely high temperature resistance for temperatures up to 1000 °C.

Insulating

Good thermal and electrical insulation properties.

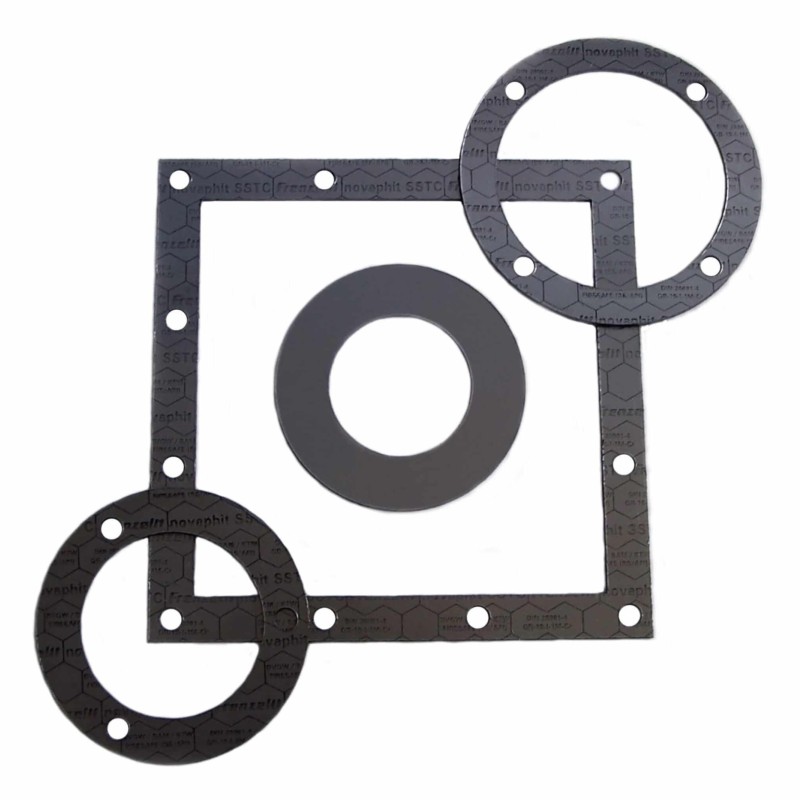

Klinger & Frenzelit

Novamica® seals from Frenzelit as well as Klinger® Milam PSS seals from Klinger.

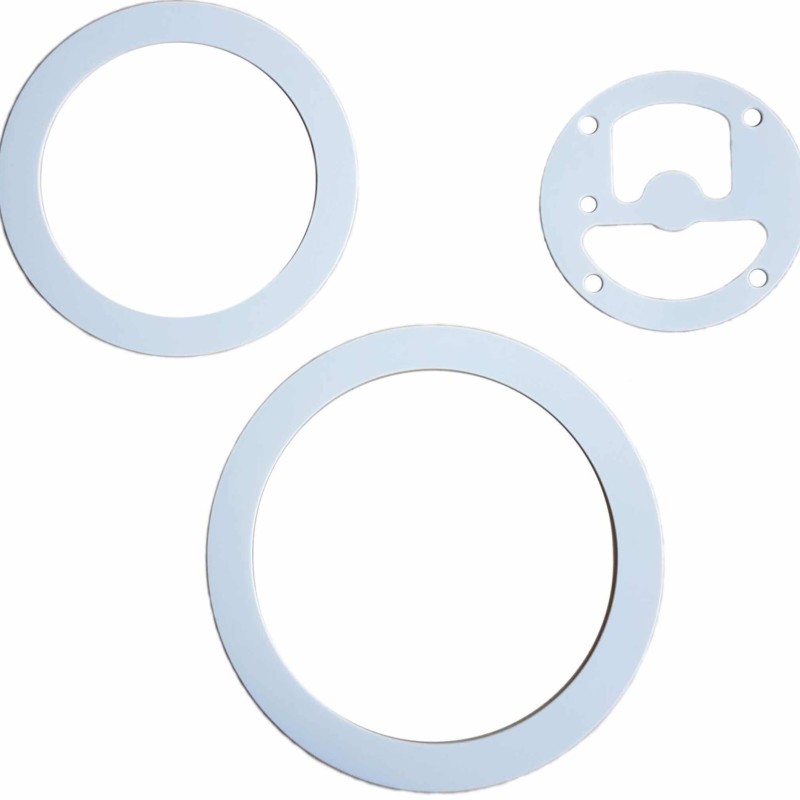

CHARACTERISTICS

Phlogopite mica gaskets are based on high-quality, refined phlogopite mica, which is far superior to other types of mica in terms of temperature resistance. Combined with a high-performance binder system, seals made of phlogopite mica open up a wide range of applications in the high-temperature range. The first-class long-term performance of the materials is achieved by an extremely low binder content. Seals made of phlogopite mica provide reliable solutions for applications that cannot be covered by conventional sealing materials. Gaskets made of phlogopite mica are characterized by extreme temperature resistance up to 1000 °C, high chemical resistance - also against aggressive and corrosive media, good thermal and electrical insulation properties, is non-flammable, good adaptability to flange unevenness, reliable long-term performance even at the highest temperatures and extremely low binder content ensures long-term stability.

In our range you will find both Novamica® seals from Frenzelit and Klinger® Milam PSS. Both represent the state of the art in phlogopite mica seals.

Benefits

- Extremely temperature resistant up to 1000 °C

- High chemical resistance - also against aggressive and corrosive media

- Good thermal and electrical insulation properties

- Non-flammable (DNI = does not ignite - according to ASTM SAE J369 burn test)

- Good adaptability to flange unevenness

- Reliable long-term performance even at the highest temperatures

- Extremely low binder content ensures long-term stability

- Novamica® seals from Frenzelit

- Klinger® Milam PSS Seals from Klinger

-

Downloads

Data sheet Novamica® Thermex

Product properties, typical applications and availabilities.

Data sheet Novamica® 200

Product properties, typical applications and availabilities.

Data sheet Novamica® 100Reel

Product properties, typical applications and availabilities.

Data sheet Klinger® Milam PSS

Product properties, typical applications and availabilities.

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.