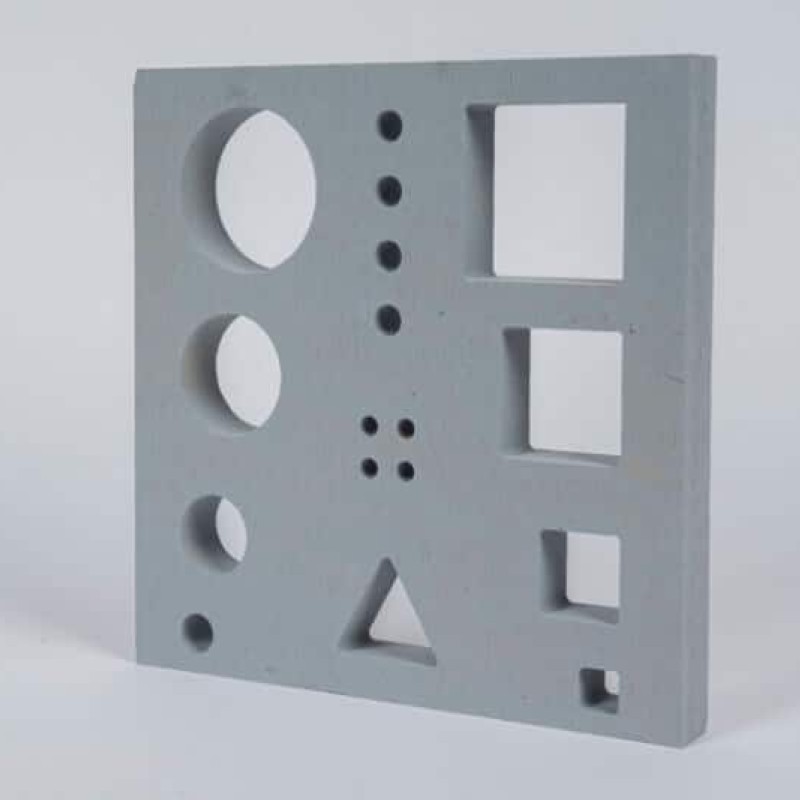

Calcium silicate mouldings

Calcium silicate mouldings maintain their dimensional stability even under extreme conditions and are suitable for temperatures up to 1,100 °C.

- PRODUCT VARIATIONS

- CNC machined | CNC drilled | CNC sawn | Pressed parts according to customer specifications

-

Temperature resistance

High temperature resistance with application temperatures up to 1100°C.

Thermal conductivity

Low thermal conductivity, non-flammable and highly shock resistant.

Thermal insulation

Suitable for fire protection and thermal insulation products.

CHARACTERISTICS

Calcium silicate mouldings maintain their dimensional stability even under extreme conditions and are suitable for temperatures up to 1,100 °C. Fire protection and thermal insulation products made of calcium silicate protect people and equipment, save space and energy, and improve processes and efficiency.

The calcium silicate plates are processed into CNC milled parts or pressed parts according to customer specifications of our own production.

Benefits

- High temperature resistance

- Application temperatures up to 1100°C

- Low thermal conductivity

- Non-flammable

- High Shock Resistant

- Fire protection products

- Thermal insulation products

- Energy-saving

- Efficiency-enhancing

-

Downloads

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.