Vermiculite paper | VIREpaper

KS VIRE®Paper 600HT is a non-respirable, cost-effective material as an alternative to silicone and ceramic fiber sealing materials.

- Strength

- 3mm | 6mm

-

Cost-oriented

Technically excellent and cost-oriented solution.

Nontoxic

Light, non-toxic, fiber-free, odorless and acid-resistant.

Refractory

Depending on the product variation, application temperatures up to 1100 ° C.

TECHNICAL DETAILS

Physical Properties

Strength 3 mm 6 mm Basis weight approx. 400 g/m2 approx. 660 g/m2 Tensile strength Longitudinal40 kg/25mm cross 46 kg/25mm Longitudinal 60 kg/25mm cross 68 kg/25mm Short term fire resistance 1100 °C 1100 °C Thermal conductivity

24 °C 0,032 W/mK 120 °C 0,047 W/mK 260 °C 0,069 W/mK 400 °C 0,112 W/mK 500 °C 0,138 W/mK 600 °C 0,158 W/mK CHARACTERISTICS

KS VIRE®Paper 600HT is a non-respirable, cost-effective material as an alternative to silicone and ceramic fiber sealing materials. It is ideal for applications where a high level of thermal insulation is required where space is limited. The special coating with KS VIRE®Shield offers additional advantages.

KS VIRE®Paper 600HT is used for high-temperature seals and flat seals for industrial ovens, water heaters, automotive, wood-burning stoves and boilers.

Benefits

- Short-term fire resistance up to 1100 ° C

- Does not stick to the flanges according to temperature

- Made from non-respirable E-glass fibers

- Permanent temperature up to 600 ° C without shrinkage

- Moisture repellent

- Achieves the highest level of non-flammability according to UL 94V-0

- Formaldehyde-free binder

- Low smoke development, low odor development

- Flexible enough to adapt to a 90 ° bend.

-

Downloads

Data sheet VIREpaper 600HT-3

Product properties, typical applications and availabilities.

Data sheet VIREpaper 600HT-6

Product properties, typical applications and availabilities.

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

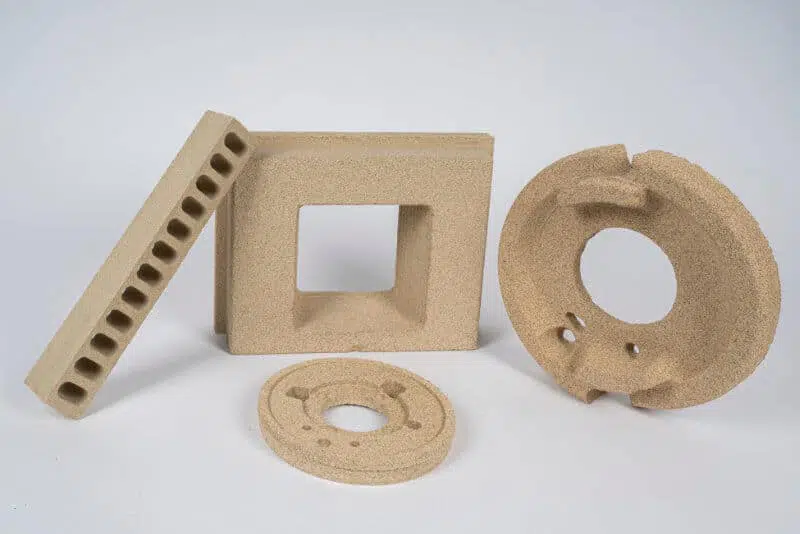

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.