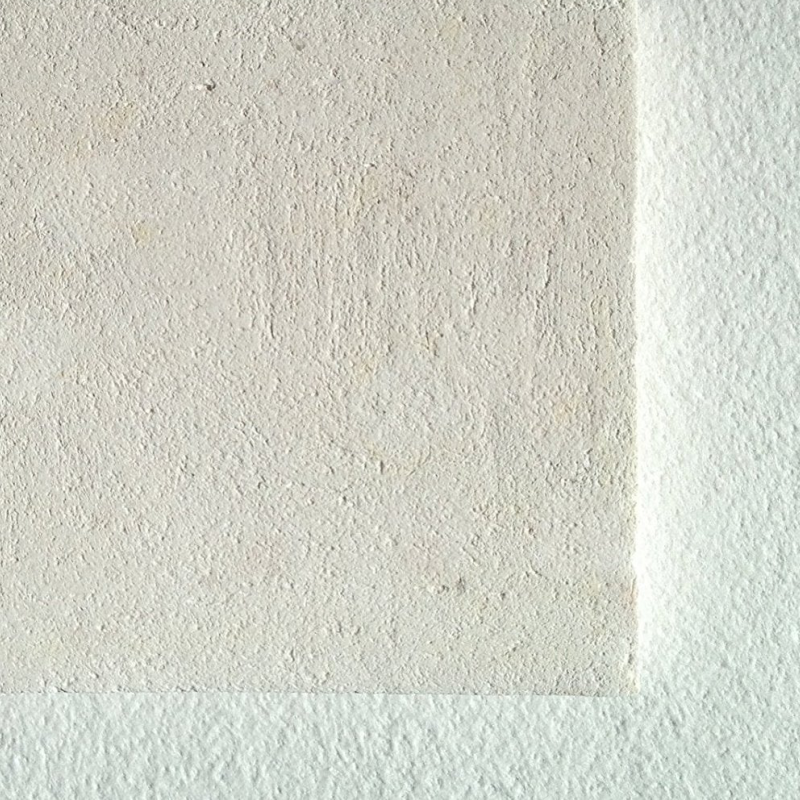

Ceramic fiber boards | Aluminum silicate wool boards

They show high temperature resistance in continuous use at temperatures up to 1400°C.

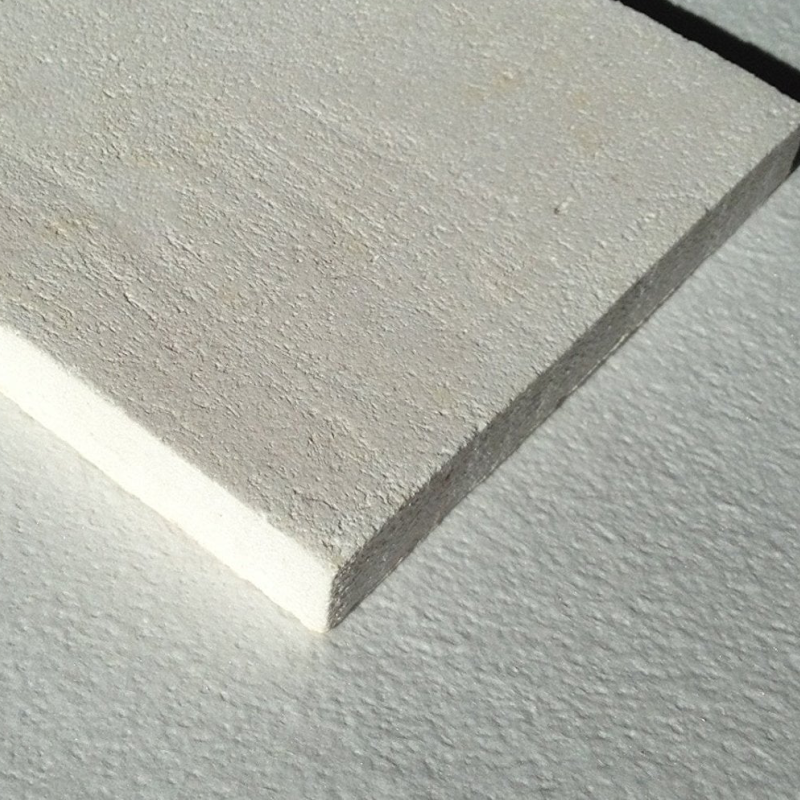

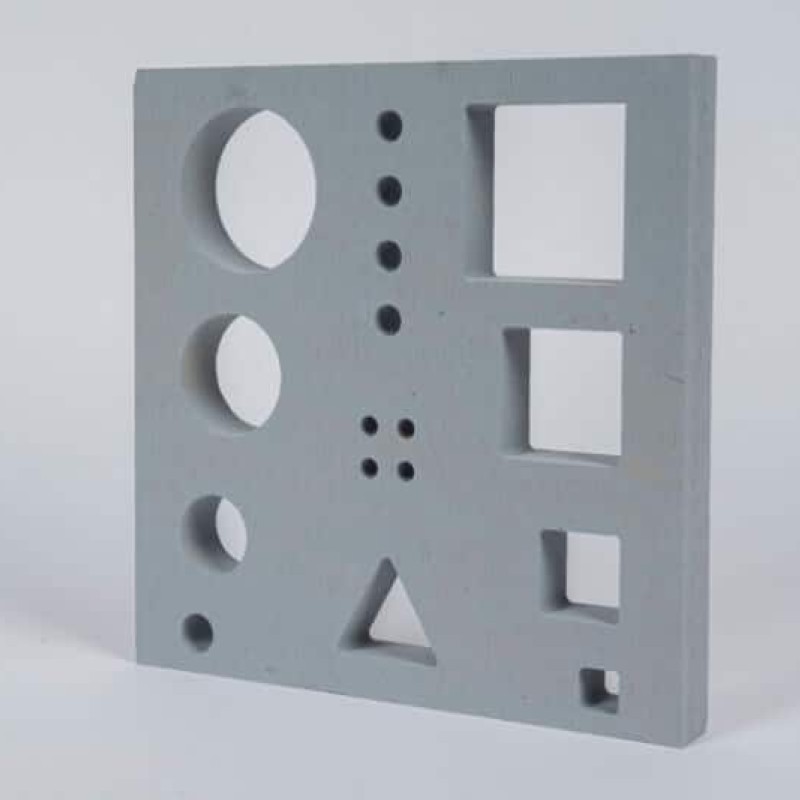

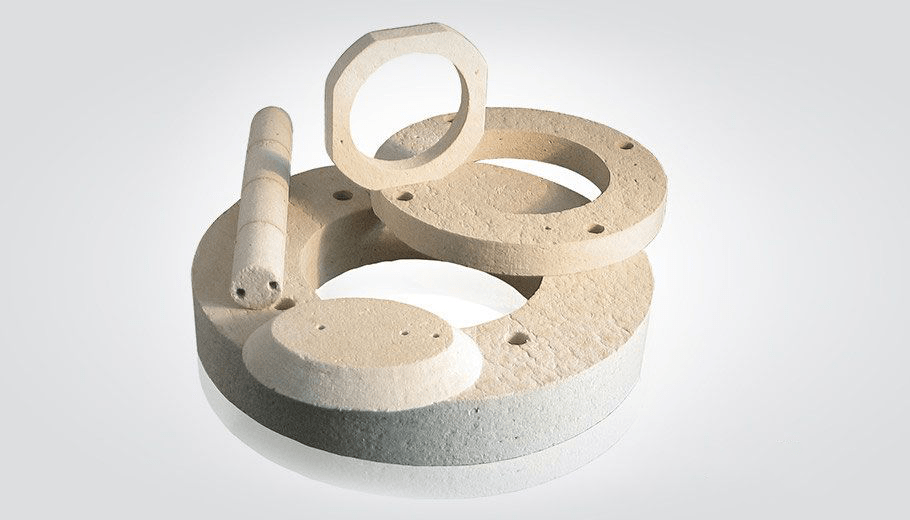

Ceramic fiber board | aluminum silicate wool board is a special high temperature insulation board, heat resistant up to 1260°C/ 2300°F or with addition of zircon up to 1400°C / 2552 °F, in various densities. The board is made of special ceramic fiber blends and is a vacuum-formed product characterized by lightness combined with hardness and excellent strength. It does not retain heat and has low thermal conductivity at high temperatures. It is very easy to cut, shape and shear, which makes the construction and installation very fast and easy.

- PRODUCT VARIATIONS

- Tissue | Bands | Knitted sealing cords | Twisted cords packs | Hoses | Mats | Blankets | Gaskets | Moldings

-

Temperature resistance

High temperature resistance with application temperatures up to 1400°C.

Thermal conductivity

Low thermal conductivity, non-flammable and highly shock resistant.

Dimensional stability

Good dimensional stability we also good flexibility.

KS Ceramic Fiber Boards | Aluminum Silicate Wool Boards are particularly suitable for lining furnaces in the glass and ceramics industries - resistant to high velocity gas flows - for complete protection of forges, for lining boilers and chimneys.

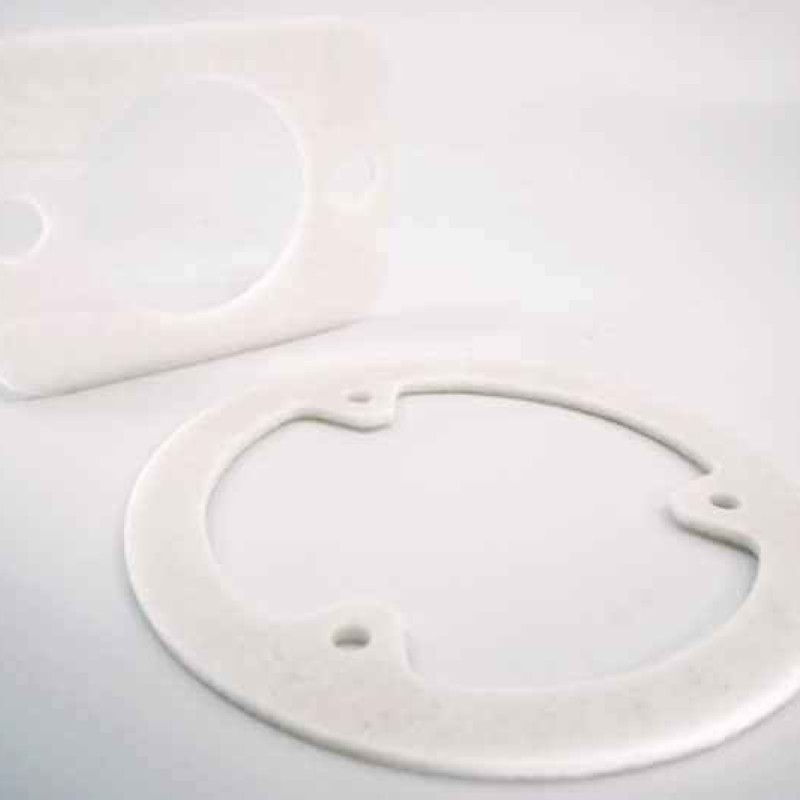

Also recommended for specific applications, such as: burner door insulation, side walls and baffles or combustion chamber cover plates, furnace linings, burner flange gaskets, weld seam protection plates, insulation plates for fireplaces, tiled stoves, oil boilers, gas boilers, radiant heaters.

- KS-ASW/RCF-1250 (Fiberfrax S ® or Ceraboard 100 ®)

- KS-ASW/RCF-1400 (Fiberfrax Z ® or Ceraboard 115 ®)

- KS-ASW/RCF-1600 (Saffil®)

Special qualities available on request!

Note: For information on precautions for handling and use of ceramic fibers as well as health risks, please refer to our EC Safety Data Sheet.

Properties

- Excellent insulation properties

- High temperature resistance

- High compressive strength

- Low thermal conductivity

- High shock resistant

- Non-combustible

- High mechanical stability

- Good chemical resistance

- Low sound transmission

- Good dimensional stability

- Easy to machine and cut

Applications

- Refractory lining of industrial furnaces

- Coating of the hot side of ceramic furnaces

- Coating of mechanical and metallurgical heating furnaces

- Thermal insulation of the back wall of industrial furnaces

- Thermal insulation for heat treatment furnaces

- Fire protection and high temperature muffle

- Barrier against flames and heat

- Combustion chambers, boilers and furnaces

- Heat resistance for fireplaces

- Support insulation for monolithic refractory materials

- Thermal insulation for glass furnaces

- Coatings for reduction cells in aluminum factories

- Wall and back wall linings for petrochemical and metallurgical industries

Delivery note: KS Ceramic Fiber Panels | Aluminum Silicate Wool Panels can be delivered as sheet goods loose on pallet or packed in cartons, but of course cut-to-size according to your desired shape is also possible.

-

Downloads

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.