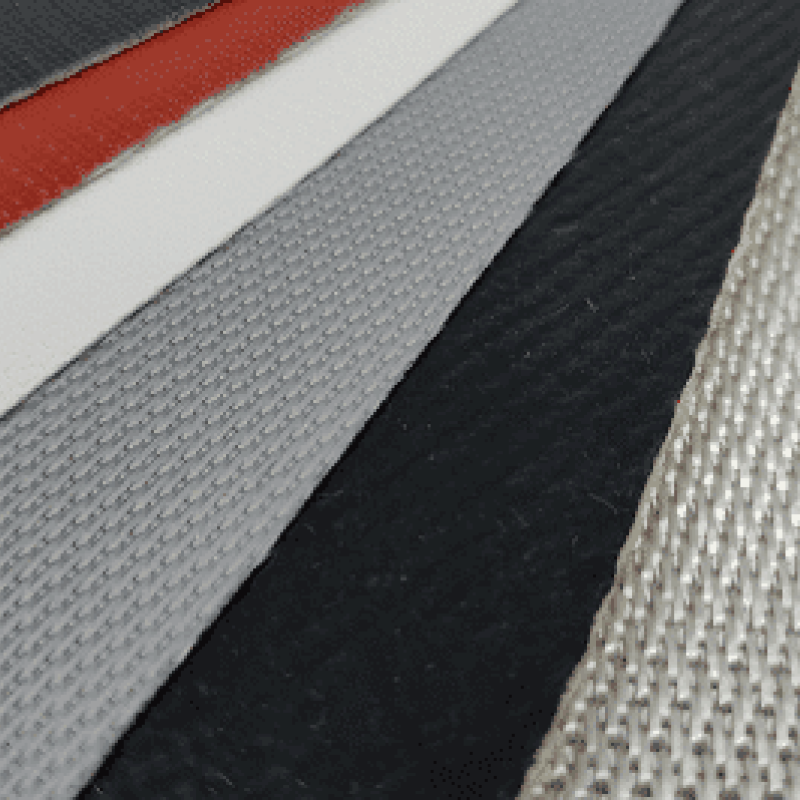

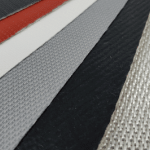

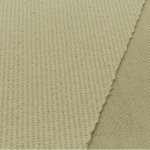

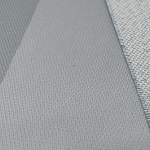

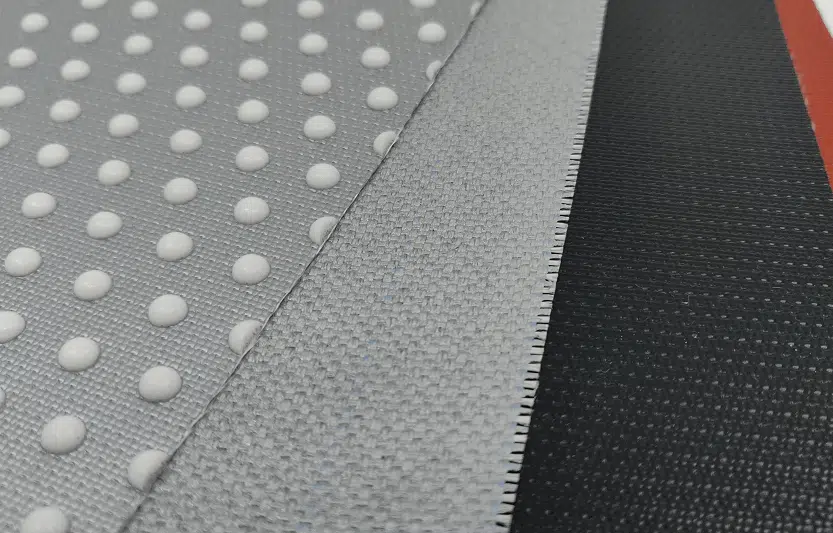

High temperature fabric

We offer High-temperature resistant fabrics and textiles in various material qualities. All fabrics can be offered with different coatings or finishes.

- Material quality

- Meta - Aramid | Para-Aramid | Preox fiber | Glass fiber | Glass fiber with V4A | HT-Glass fiber | Silicate fiber | Ceramic fiber

-

Temperature resistance

Max. Application temperature, depending on material, up to 1100°C.

Thermal conductivity

Low thermal conductivity, non-flammable materials.

Stable & Durable

Chemical resistance, mechanical stability and flexibility.

CHARACTERISTICS

We offer High-temperature resistant fabrics and textiles in various material qualities. All fabrics can be offered with different coatings or finishes. Depending on customer requirements, adapted fabric thicknesses can also be produced via weave patterns and thicknesses of warp & weft.

High temperature fabrics are woven in Europe and are among the highest quality fabrics. Well-known fibre manufacturers stand for consistently high-quality raw materials. High temperature resistant fabrics and textiles are used in various industries and products such as personal protective equipment (PPE), steel and iron foundry, electrical insulation, automotive etc. and of course in our sister company for the production of RBS fabric compensators or RBS textile confections.

Benefits

- Temperature resistance

- Max. Application temperature, depending on material, up to 1100°C

- Low thermal conductivity

- Mechanical stability

- Non-flammable

- Different dimensions (width & length)

- Flexibility

- Chemical resistance

- Various finishes (graphitized, siliconized, vermiculite,...)

Werkstoffe

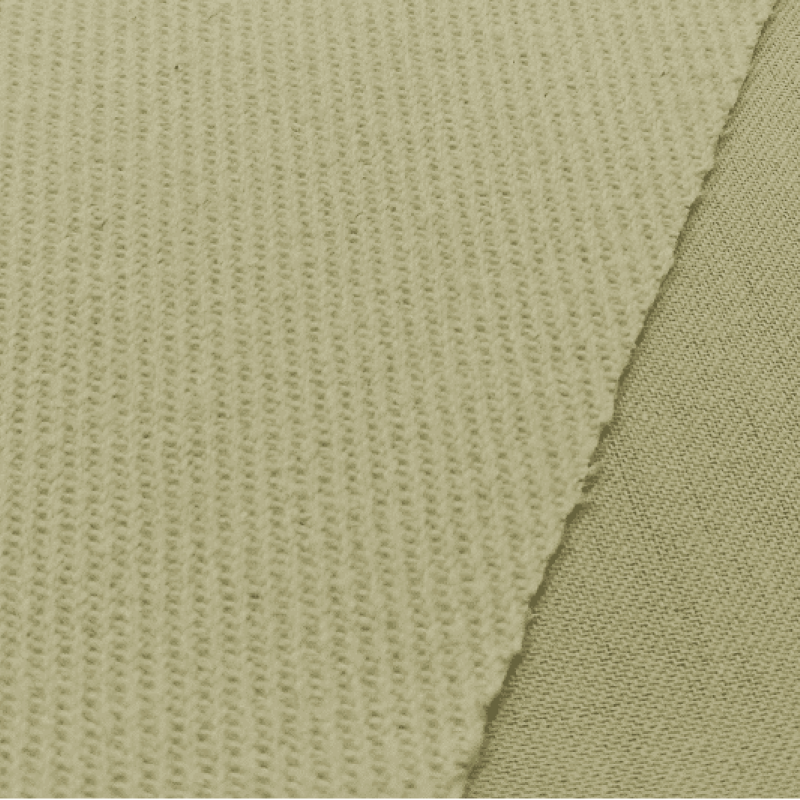

Meta-Aramid

- Up to 220°C

- LOI- Value (Limited Oxygen Index) 29%

- Permanently non-flammable

- No melting and dripping

- Chemical resistance

- Dimensional stability

- Abrasion and tensile strengths

- Unclassified material

APPLICATIONS

- Firefighting clothing

- Police

- Protective work clothing

- Textile expansion joints

Para-Aramid

- Up to 380°C

- Tensile strengths

- Temperature resistance

- Chemical resistance

- Self-extinguishing

- Low thermal conductivity

- Unclassified material

APPLICATIONS

- Protective clothing

- Cable protection

- bellows

- Machine cladding

- Protective gloves

- Textile expansion joints

Preox

- Up to 475°C

- LOI VALUE (Limited Oxygen Index) 50%

- Temperature resistance

- Chemical resistance

- Low thermal conductivity

- Available in 50/50 and 70/30 blends

- Unclassified material

APPLICATIONS

- Protective clothing

- Cable protection

- bellows

- Machine cladding

- Protective gloves

- Textile expansion joints

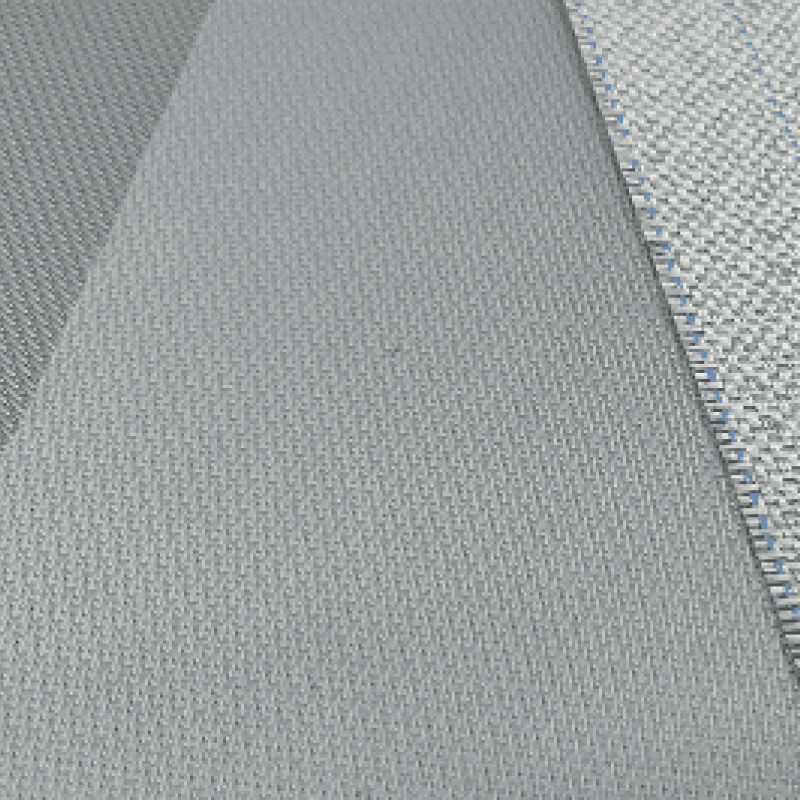

Glass fiber

- Up to 550°C

- Temperature resistance

- Chemical resistance

- Tension E-module GPa 73

- Low thermal conductivity

- Unclassified material

APPLICATIONS

- Cable protection

- Pipe insulation

- Insulation cushion

- Fire/welding protection

- Carrier material

- Textile expansion joints

Glass fiber with V4A

- Up to 600°C

- High-temperature resistance due to V4A

- Non-burning and non-dripping

- Chemical resistance

- Tension E-module GPa 73

- Low thermal conductivity

- Unclassified material

APPLICATIONS

- Cable protection

- Pipe insulation

- Insulation cushion

- Fire/welding protection

- Textile expansion joints

HT-glass fiber

- Up to 750°C

- Temperature resistance

- Chemical resistance

- Tension E-module GPa 73

- Low thermal conductivity

- Unclassified material

APPLICATIONS

- Cable protection

- Pipe insulation

- Insulation cushion

- Fire/welding protection

- Carrier material

- Textile expansion joints

Silicate fiber

- Continuous filament fiber up to 1000°C

- Staple fiber up to 1100°C

- Temperature resistance

- Low thermal conductivity

- Mechanical stability

- Non-flammable

- Flexibility

- Chemical resistance

- Unclassified material

APPLICATIONS

- Cable protection

- Pipe insulation

- Insulation cushion

- Fire/welding protection

- Carrier material

- Textile expansion joints

Ceramic fiber

- Glass reinforced up to 650°C

- Stainless steel reinforced up to 1100°C

- Temperature resistance

- Low thermal conductivity

- Mechanical stability

- Non-flammable

- Flexibility

- Chemical resistance

- Classified material

APPLICATIONS

- Cable protection

- Pipe insulation

- Insulation cushion

- Fire/welding protection

- Carrier material

- Textile expansion joints

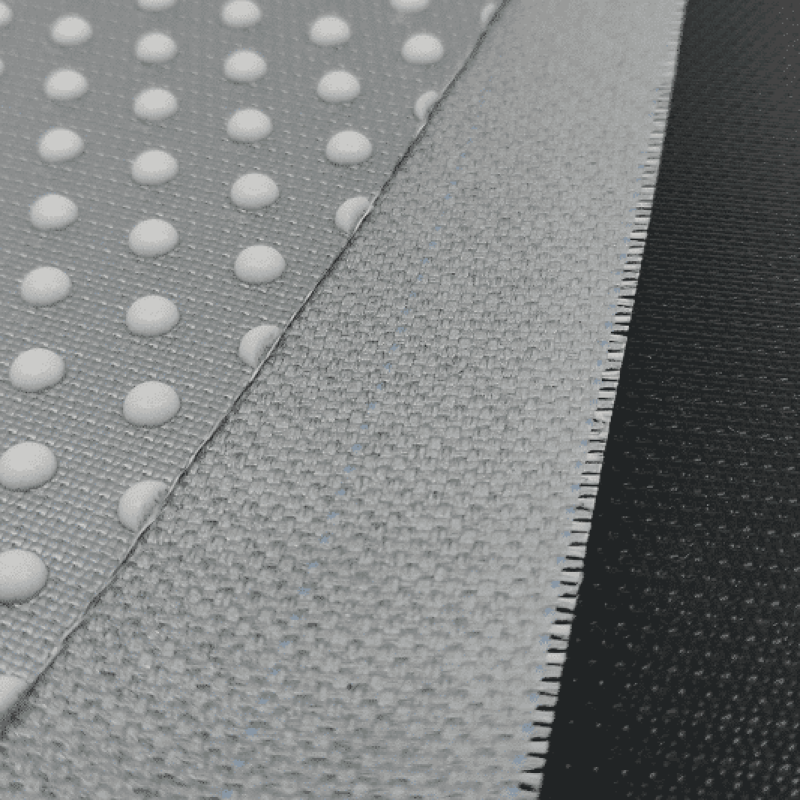

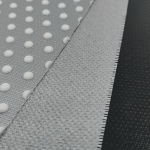

EQUIPMENT

All fabrics can be coated with various coatings

or equipment is offered:- silicone

- PTFE

- Vermiculite

- graphite

- polyurethane

- div. HT (high temperature) equipments

- Cut Resistant Equipment

- Self-adhesive coating

- preshrunk

- Etc.

Depending on customer requirements, different fabric thicknesses can be produced using various weave patterns and thicknesses of warp and weft.

-

Downloads

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.