Twisted cords

Twisted cords are made by twisting several yarns together. The diameter of the cord depends on the number and thickness of the threads.

- Material

- E-Glass fiber, HT-Glass fiber | Continuous filament silk fiber | Earth alkaline silicate fiber | Silicate staple fiber | Aluminium silicate fibre

-

Temperature resistance

Max. Application temperature, depending on material, up to 1260°C.

Thermal conductivity

Low thermal conductivity, non-flammable materials.

Stable & Durable

Chemical resistance, mechanical stability and flexibility.

CHARACTERISTICS

Twisted cords are made by twisting several yarns together. The diameter of the cord depends on the number and thickness of the threads. Suitable as sealing cords for stoves, tiled stoves, boilers, flue gas and ventilation dampers, as expansion joints for heating cassettes, furnace and plant construction, expansion joints in the high temperature range, etc. at temperatures up to 1260°C.

Depending on the application and temperature, various materials are available - See Technical details.

Benefits

- Temperature resistance

- Max. Application temperature, depending on material, up to 1100°C

- Low thermal conductivity

- Mechanical stability

- Non-flammable

- Different dimensions (width & length)

- Flexibility

- Chemical resistance

- Various finishes (graphitized, siliconized,...)

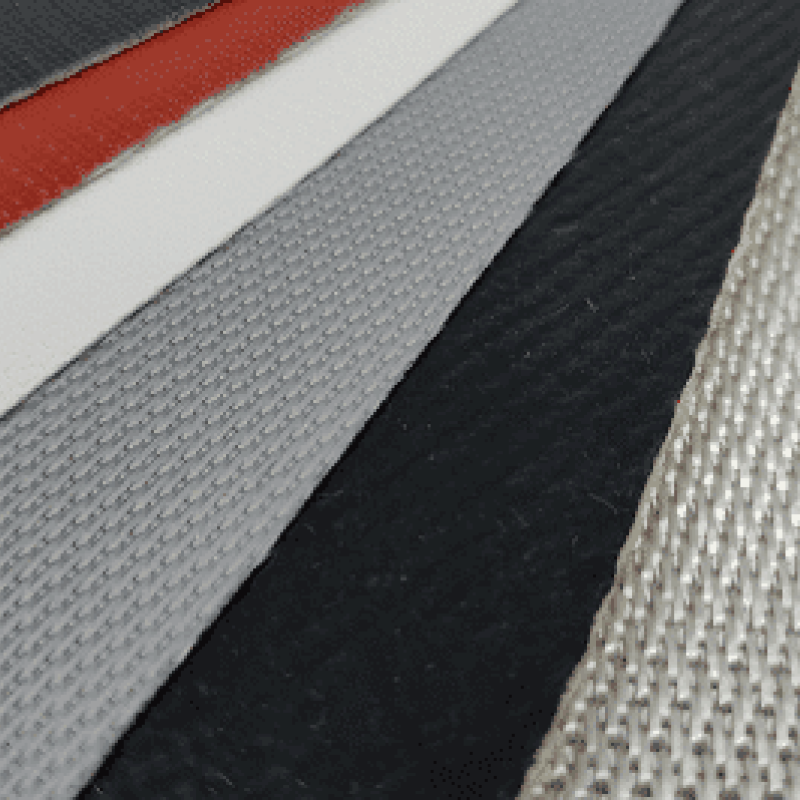

EQUIPMENT

All fabrics can be offered with various coatings or equipment:

- silicone

- Vermiculite

- PTFE

- graphite

- polyurethane

- div. HT (high temperature) equipments

- Cut Resistant Equipment

- Self-adhesive coating

- preshrunk

- Etc.

Depending on customer requirements, different fabric thicknesses can be produced using various weave patterns and thicknesses of warp and weft.

TECHNICAL DETAILS

Produkt | Artiicle KS Kaldera 550 KS Kaldera 750 KS Kaldera 1000 KS Kaldera 1050 KS Kaldera 1100 KS Kaldera 1260 material E-glass fiber HT-glass fiber HT-glass fiber Continuous filament silicate fiber Earth alkaline silicate fiber Silicate staple fiber Aluminium silicate fibre Dye White Blue White, Ivory Green White White Max. Application temperature 550°C 700°C 1000°C 1050°C 1000°C 1260°C Melting point 1200°C 1200°C 1550°C 1260°C 1550°C 1790°C Fire behaviour Non-flammable Non-flammable Non-flammable Non-flammable Non-flammable Non-flammable Chemical resistance Good Good Good Good Good Good TESPE Tenute Speziali

Since TESPE was founded in 1993, they have specialized in the production of technical textiles and industrial seals for high temperatures. We use the latest materials and production techniques to guarantee the highest quality and high performance across the entire product range.

An absolutely reliable technical-commercial partner and not just a simple product supplier, always using experience and professionalism to guarantee the best consulting services, technical support, punctuality and competitiveness.

Textile assortment

Bands

Knitted sealing cords

packs

Hoses

Tissue -

Downloads

Data sheet KS Kaldera 550

Product properties, typical applications and availabilities.

Data sheet KS Kaldera 750

Product properties, typical applications and availabilities.

Data sheet KS Kaldera 1000

Product properties, typical applications and availabilities.

Data sheet KS Kaldera 1050

Product properties, typical applications and availabilities.

Data sheet KS Kaldera 1100

Product properties, typical applications and availabilities.

Data sheet KS Kaldera 1260

Product properties, typical applications and availabilities.

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

Seit 2009 ist der Betrieb nach der ISO9001 zertifiziert, aktuell lt. Normenrevision 2015.